Key Insights

- Factories are becoming more intelligent, flexible, and sustainable through the power of technology, data, and the Internet of Things (IoT).

- IoT Analytics researched how 80 of the world’s best factories became so smart and discovered that, among other things, there is much more to smart factories than technology.

Why it matters?

- Customer demands are pushing manufacturers towards shorter product lifecycles, higher customization, and quicker time to market.

- Smart factories can make the difference for manufacturers in their market success—as the example of Moderna’s Norwood, MA, factory shows.

Introduction – The smart factory as a competitive advantage

Moderna, the American biotechnology company and maker of the well-known Moderna vaccine, is the poster child of how a digital-first vision applied to a smart factory can be a business game-changer in 2021 and beyond.

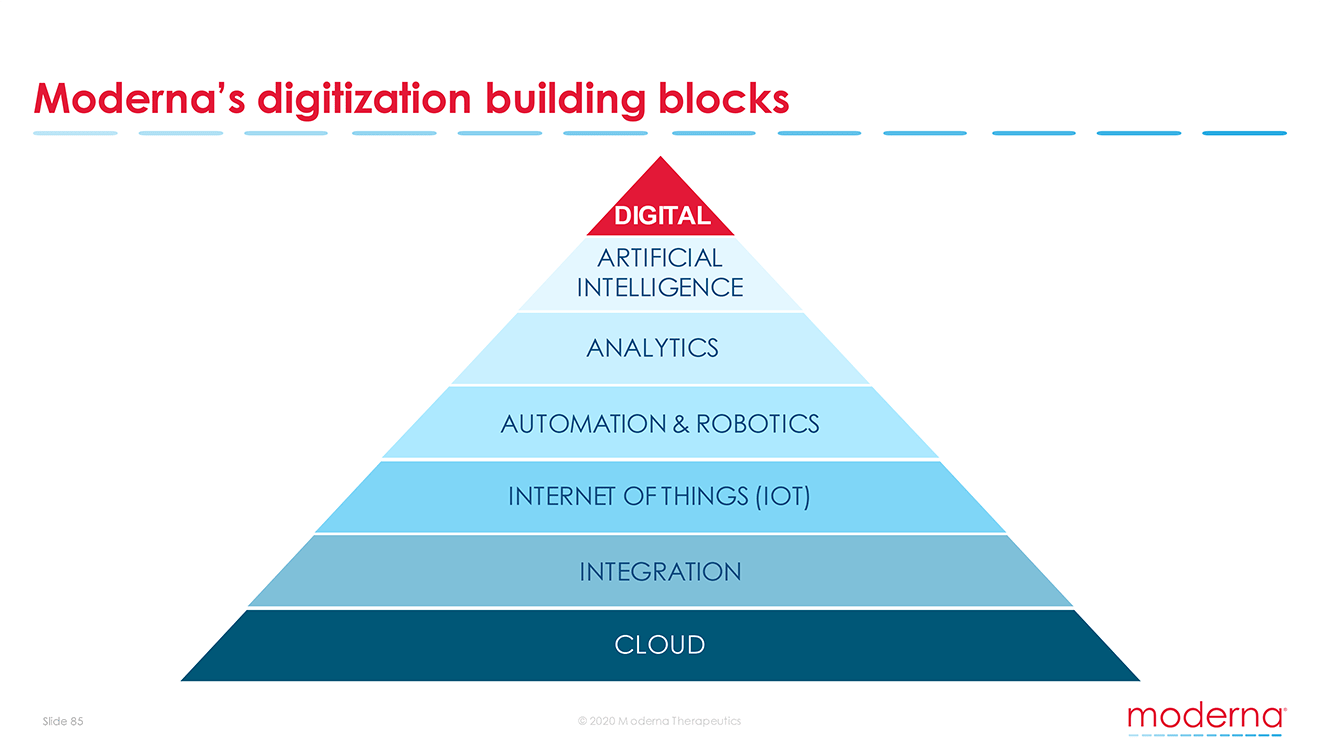

In 2018, the company invested in a new 200,000-square-foot manufacturing site in Norwood, Massachusetts as part of its 10-year vision to “integrate automation and digital technology into everything we do.” The company equipped the factory with various state-of-the-art digital technologies that enabled end-to-end testing, developing, and scalable manufacturing capabilities for mRNA drug candidates. Some of the latest robotics, automation, AI, data analytics, and blockchain technology were deployed to create a digitally connected ecosystem or a “smart factory.” The goal was to be able to use the digitally advanced factory to scale up production quickly and with agility, according to the market need.

In 2020, Moderna’s smart factory was put to the test by the COVID-19 pandemic. In July 2020, the company became one of the first US companies to enter phase III of a clinical trial for a potential coronavirus vaccine, just months after the genetic code of the virus was released.

The smart factory became a cornerstone for Moderna to accelerate the vaccine development process in several ways, including using AI-based algorithms for massive sequence optimization and using digital twin technology to rapidly simulate and test the related production processes. This vaccine development process, which usually takes an average of 10 years, was reduced to months, in part thanks to Moderna’s previous investments in smart factory technologies. (Link)

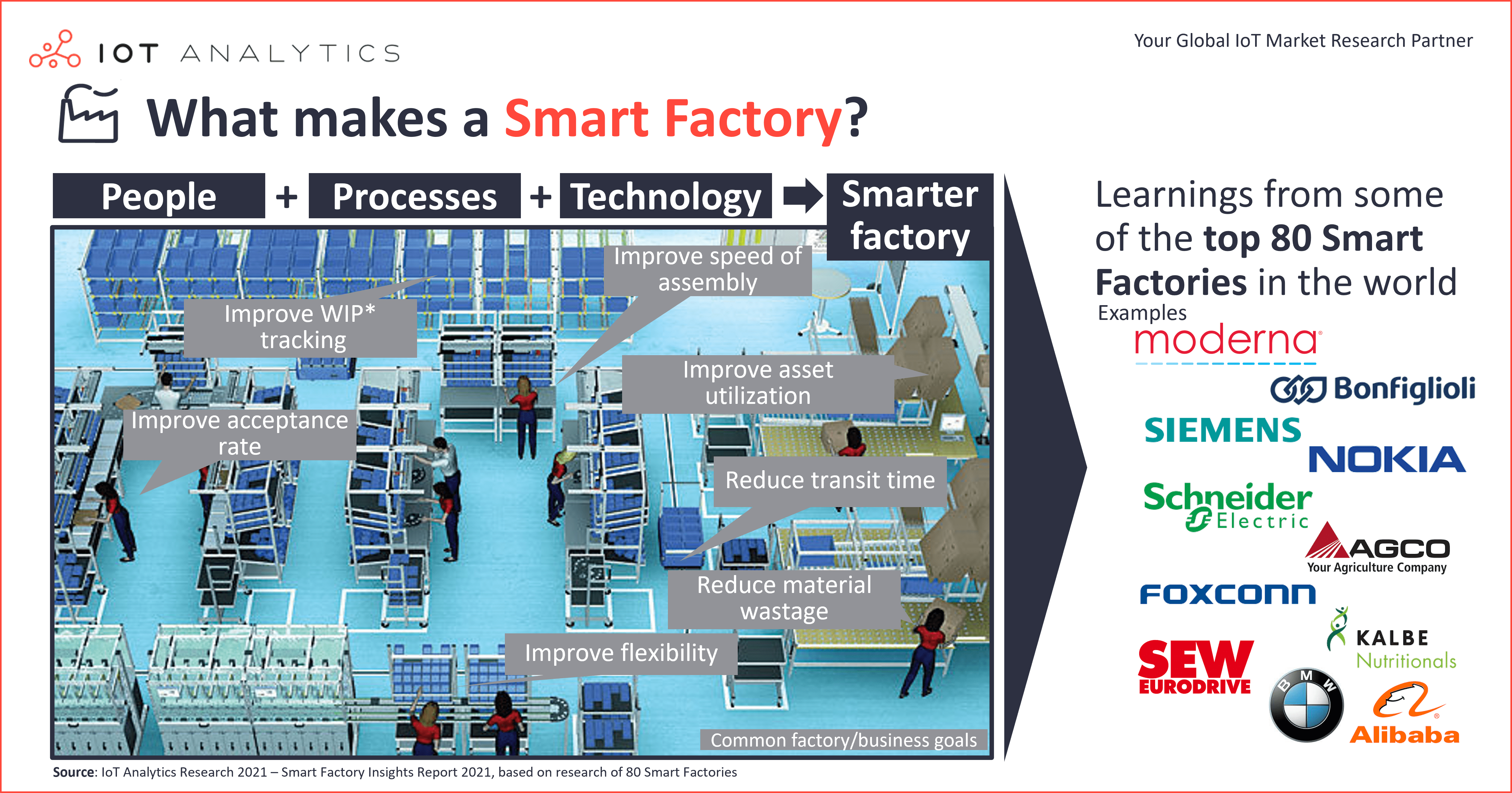

Our latest research on smart factories shows that Moderna’s facility is a prime example of a new generation of factories that are more agile, sustainable, collaborative, and efficient than many of the factories that exist today. The 163-page Smart Factories Insights Report 2021 discovered 80 such factories, portrayed 10 of them in detail, and highlighted commonalities and best-practices. Our analysis of these also uncovered some common misconceptions about what it takes to realize a smart factory.

What a smart factory really is – a definition

Based on our research, a smart factory is “the holistic transformation of people, processes, and technologies along with the use of data to achieve the intended performance/business goals of one or more production site(s).”

It is important to understand that a smart factory is not a destination or an end goal, but a journey that all manufacturing organizations can embark on at their own pace. The “smartness” of a factory is measured on a spectrum. Factories of all shapes and sizes can assess their maturity and begin their journeys (e.g., by using digital maturity models, such as the Acatech model or Fraunhofer’s I4.0 assessment model, which are discussed in the report). According to our research, this amorphous nature of smart factories has led to the formation of seven common misconceptions, which are discussed below.

Seven misconceptions about smart factories

1. Smart factories must be started from scratch (greenfield projects).

WRONG. For sure,greenfield smart factory projects (i.e., new factories built from scratch) are easier to realize because there is no existing infrastructure to upgrade and no existing processes that could be disrupted, making planning and implementation much easier. Our research, however, shows that many existing (brownfield) facilities are also becoming smarter, in some cases with worldwide recognition.

Industrial automation vendors are at the forefront of showcasing how a brownfield smart factory transformation can be achieved. Here are two examples:

- Schneider Electric has showcased how its own technologies (e.g., EcoStruxure platform, AVEVA platform) are in use at their own factories. The Schneider Electric facility in Lexington, USA, was recognized as an advanced lighthouse factory by the World Economic Forum in 2020.

- Siemens Electronics Works plant in Amberg, Germany was also recognized as an advanced lighthouse factory by the World Economic Forum in 2021. Using the company’s own solutions, from Siemens Cloud infrastructure to digital twins, the plant has achieved a 50% increase in efficiency and now serves as a guideline for other smart factories.

2. Only large organizations can realize smart factories.

WRONG. It is true that IoT Analytics research from 2019 shows that big companies are further along and less budget-constrained, but there are ways that make realizing smart factories viable for smaller companies as well. Here are some examples:

- Financial support. There are several industry associations, like CESMII in the U.S. or the Gaia-X community in Europe, that provide subsidies and support for SMEs who are looking to make their factories smart.

- Determine viability. Non-profit smart factory initiatives, like Smart Factory OWL and Smart Factory KL, allow manufacturers to witness and test certain technologies off-site and discuss them with like-minded professionals before spending on them.

- Pay per use. A notion exists that smart factory initiatives involve a lot of CAPEX, infrastructure, and data upgrading and hence are not suitable for SMEs. The rise of as-a-service business models (mostly for software but also increasingly for everything else, including expensive equipment), pushes those costs to OPEX, bringing smart factories within the reach of SMEs.

3. There is a one-size-fits-all blueprint for realizing a smart factory.

WRONG. Unfortunately, no two smart factories look exactly alike because each has different production characteristics, and, perhaps even more importantly, each has its own performance/business goals.

In our research, we identified eight typical performance/business goals, which we grouped into three types: operational, commercial, and R&D. The examples below highlight how different goals can lead to different types of smart factory deployments (in this case the Moderna plant has a different goal than the Trumpf factory). Examples:

- Moderna (Operational goal—Improving agility). The Moderna example discussed earlier is an example of how increased agility created by a smart factory created tremendous value. In this case, time to market was crucial, not just for the company, but for the entire world, and investments in the smart factory ended up eventually paying huge dividends for Moderna, whose stock ended 2019 at <$20/share and today is trading at ~$400/share.

- TRUMPF (Commercial goal—Showcasing new offerings). TRUMPF’s €30M Smart Factory in Chicago realizes TRUMPF’s vision of networked production and acts as a showcase for TRUMPF customers. One of the main goals of the factory is to showcase the art of the possible and help customers of TRUMPF realize their own smart factories.

4. Smart factory initiatives are mostly about technology.

WRONG. While new technology is often a key part of a smart factory transition, it is not the only part and, according to our research, not the most important one. Almost all smart factory practitioners that we have interviewed in the last two years have pointed us toward the importance of less tangible aspects, mostly related to people and processes within an organization. In fact, when asked about the success factors of Industry 4.0 initiatives, only one of the top 10 success factors revolved around technology.

One particularly important concept to consider is change management, which is required to ensure that the transformation process is transparent and that employees feel included throughout the process. Example:

- Infineon introduced change ambassadors at their factory in Singapore (Link). In 2017, Infineon, a Germany-based global electronic and semiconductor manufacturing company, announced a five-year transformation roadmap for its manufacturing site in Singapore. To engage employees right from the start, members of the workers union were appointed as change ambassadors to facilitate two-way communication of new initiatives and promote feedback between shopfloor staff and management.

5. Smart factory initiatives replace existing continuous process improvement projects.

WRONG. Smart factory initiatives need to work alongside existing process improvement tools (e.g., Lean Manufacturing, Six Sigma) rather than replace them.

Our research shows that Smart factory technologies play a vital part in automating aspects of data collection and analysis, and in eliminating inefficiencies and errors associated with manual processes, thereby improving the efficiency of the continuous improvement process.

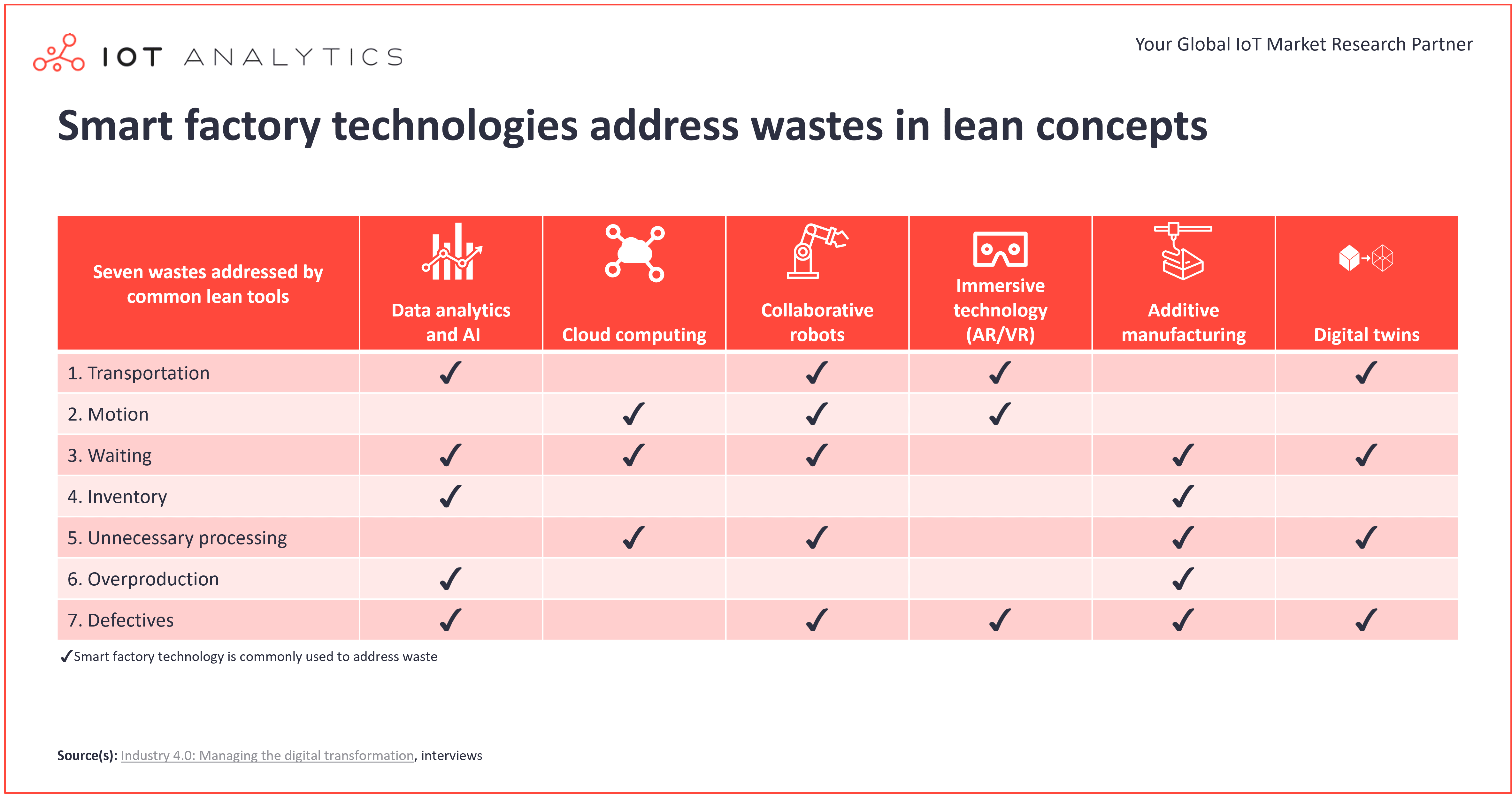

Even though the “Lean” methodology in its purest form avoids significant technological assistance, many practitioners now try to use various smart factory technologies to help eliminate different wastes. The picture below shows some selected smart factory technologies and which of these can help with which forms of waste.

6. Scaling the successes at one factory to other factories in the network is easy.

WRONG. Scaling from one smart factory to several others is often the most difficult part because each factory setup is inevitably different from the predecessors, with both the tangible (machine conditions, IT landscape, product features) and intangible conditions (employee mindset, management mindset) being entirely different in different locations.

The journey of a smart factory often begins with a single digital use case and quickly grows into a mesh of technologies and use cases. Approaches on how to navigate the strategic decisions around scaling a smart factory approach vary.

Some companies find that it is easier to first try out some of the technologies and use cases in an existing factory before building a new smart factory from scratch (greenfield). Example

- Siemens. The German conglomerate invested heavily into digitizing its existing Amberg plant before deploying a similar setup, with very minor local modifications, at its greenfield Chengdu plant in China. Siemens claims that, on a technology and process level, the plant is a one-on-one replication of the Amberg plant. (Link)

Other companies have employed the opposite approach. Rather than building a new smart factory based on best practices from an existing plant, they build a new flagship plant and use it as the central element in their smart manufacturing network strategy. Example:

- Bonfiglioli. In 2016, Bonfiglioli, an Italian manufacturer of power transmission components, introduced its “EVO” (short for evolution) strategy to build technologically advanced smart factories. The company built a new flagship factory at its Clemintino Bonfiglioli site, Italy, and is now using the plant to recruit new employees, train existing employees, and continuously transfer technologies and methodologies to its other plants in various locations worldwide. (Link)

7. A smart factory must be fully automated.

WRONG. While many smart factories contain highly automated systems, automation is not a prerequisite for realizing the goals of smart factories.

According to our research, data, not automation, is the key foundation underpinning all smart factory use cases. Technology that enables the acquisition, orchestration, and analysis of relevant data will empower the humans running the factory to make faster, more informed, and ultimately better decisions. Example:

Hugo Boss. Apparel manufacturing is considered one of the most labor-intensive industries. Hugo Boss’s apparel manufacturing smart factory in Izmir, Turkey, has implemented technologies such as augmented reality, machine learning, cloud computing, and data analytics alongside its 3,500 workers to produce suits, jackets, shirts, and coats. The factory improves efficiency by using more than 1,600 Wi-Fi-enabled tablets to capture data and empower front-line employees with order and operational data. (Link)

Conclusion

As the example of the Moderna smart factory has shown, investing in production technology, personnel, and processes can pay enormous dividends. Today’s generation of smart factories is not necessarily characterized by heavily high-tech greenfield installation. Due to the rapid change in customer preferences and the availability of promising technologies, companies of all shapes and sizes can (and should) have a comprehensive smart factory strategy in 2021—regardless of their current digital maturity. The messaging is clear: Companies that have already embarked on their smart factory journey will continue to adapt better to the dynamic business environment and grow faster than those that have not.

Here are three action points that, based on our research, have worked for several manufacturers to start their smart factory journey:

- Action point 1: Focus on a use case and not a technology. Out of the many use cases out there, pick an applicable high-ROI, high benefit use case and then experiment with suitable technologies. (Note: IoT Analytics has performed several IoT use case analyses and measured ROI of each, e.g., in 2019 as part of the Industry 4.0 Adoption Report. We will publish a new IoT Use Case Adoption Report in September 2021, based on input from 200+ practitioners.)

- Action point 2: Do not wait for employee engagement. Engage front-line workers from the beginning of the smart factory project. Alleviate their doubts through transparent communication and empower them through upskilling efforts. Communicate, communicate, communicate.

- Action point 3: Tie the smart factory to an existing process improvement initiative. Support the initiative with smart factory technologies to make processes more efficient with technology.

More information and further reading

Are you interested in learning more about Smart Factories?

The Smart Factory Insights Report 2021 is a comprehensive 163-page report detailing how factories are becoming smarter. It includes 10 detailed case studies of smart factories showcasing goals achieved, technologies deployed, and use cases realized. Also, there is in-depth analysis of the 3 smart factory enablers processes, people, and technology as well as a database of 80 smart factory projects around the world. It is part of IoT Analytics’ ongoing coverage of Industrial IoT and Industry 4.0 topics (Industrial IoT Research Workstream).

This report provides answers to the following questions (among others):

- How have the goals of manufacturing evolved over the years?

- How do production characteristics vary across different types of industries such as process, discrete and hybrid manufacturing?

- What are the different goals of today’s factories?

- What role do processes and continuous process improvement methods (e.g.: Lean, Six sigma) play in smart factories?

- What is the significance of employee engagement and workforce empowerment in smart factory initiatives?

- What are the ways in which technology enables smart factories?

- What are the different methods of data ingestion for a smart factory?

- What are digital maturity models for smart factories and how can they be used?

- How have different companies deployed smart factories?

- What are the key challenges and drivers of smart factory projects?

- And more…

The sample of the report gives you a holistic overview of the available analysis (outline, key slides). The sample also provides additional context on the topic and describes the methodology of the analysis. You can download the sample here:

Related articles

We publish a lot of research on Industrial IoT/Smart Factory and related topics. Here are some of our recent articles that you may be interested in:

General Industry 4.0 & Smart Factory topics

- Industry 4.0 Adoption 2020 – who is ahead?

- The Leading Industry 4.0 Companies 2019

- Will the industrial internet disrupt the smart factory of the future?

Smart Factory technology infrastructure topics

- IoT edge computing – what it is and how it is becoming more intelligent

- Soft PLCs: The industrial innovator’s dilemma

- 5 Things to Know About the IoT Platforms Market

- 5 Industrial connectivity trends driving the IT-OT convergence

Specific Smart Factory use cases

- Predictive Maintenance Market: The Evolution from Niche Topic to High ROI Application

- Cloud MES: How manufacturing software is migrating to the cloud

- Entering the decade of equipment as a service – characteristics of the machine outcome economy

- The Top 10 Industrial AI use cases

Are you interested in continued IoT coverage and updates?

Subscribe to our newsletter and follow us on LinkedIn and Twitter to stay up-to-date on the latest trends shaping the IoT markets. For complete enterprise IoT coverage with access to all of IoT Analytics’ paid content & reports including dedicated analyst time check out Enterprise subscription.