In short

- The current state of industrial automation was on full display at SPS Fair 2025.

- IoT Analytics had 4 analysts on the ground to uncover the latest trends. The team shares its initial highlights from 8 of the biggest industrial automation vendors here.

Why it matters

- SPS is one of the world’s most important industrial automation fairs. The showcased technologies are widely applicable to any industrial company.

In this article

Overview: Smart Production Solutions 2025

Smart Production Solutions (SPS) is a leading industrial automation exhibition fair that serves as a window into the state-of-the-art digital and smart automation solutions. The 2025 edition, which returned to Nuremberg, Germany, on November 25–27, 2025, saw a 9% increase in visitors.

“The SPS is a fixture on the automation industry’s calendar. If you don’t exhibit here, you don’t exist!”

Felix Kranert, Vice President Marketing for Germany, Austria, and Switzerland, at Schneider Electric

IoT Analytics had 4 analysts in attendance to witness the latest trends and understand the market positioning of key industrial automation vendors. Below are key highlights from 8 of the biggest industrial automation players. The team plans to provide deeper coverage on the event in early 2026, including:

- An article on the main industrial technology trends – as seen at SPS 2025 (early January – sign up for IoT Analytics’ newsletter to get it)

- A comprehensive SPS 2025 Event Report (early January for IoT Analytics corporate customers)

SPS 2025 highlights from leading industrial automation vendors

1. Siemens

Germany-based industrial automation company Siemens’ presence centered on the theme “Let’s automate automation together,” emphasizing a commitment to connecting the real and digital worlds through digital threads to optimize customer workflows. Key highlights included advancements in industrial AI applications, the formal launch of next-generation drive technology, and the introduction of zero-trust security principles for OT.

Key themes from Siemens at SPS 2025:

One tech company’s strategy

Siemens emphasized leveraging strong global partnerships and internal harmonization to scale technologies rapidly. Siemens is now operating under the “One Tech Company” strategy, which aims to leverage foundational technologies (such as Industrial Edge and cloud services) and shared data policies across all Siemens business units to scale faster and improve customer focus.

Industrial AI and co-pilot adoption

Industrial AI was a key theme for Siemens. The Engineering Copilot TIA, a generative AI (GenAI) tool designed to autonomously execute engineering tasks (including code programming, documentation, testing, HMI screen generation, and hardware configuration), is now expanding to additional pilot customers following a successful beta phase. Simultaneously, the Insights Hub Production Co-pilot was showcased, leveraging generative AI and agents as an optimization layer for data-driven manufacturing. This solution enables operators to interact with data using natural language, accelerating root-cause analysis and providing quick operational fixes. For example, TotalEnergies Gas Mobility, a subsidiary of France-based energy company TotalEnergies, used the Copilot Studio (generally available since September) to scale data insights across its stations, successfully replicating agent templates from pilot locations to enhance decision-making. Siemens’ long-term trajectory involves deploying agentic AI capable of autonomous production, where AI agents autonomously understand, plan, and execute tasks across entire workflows, accelerating the progress toward autonomous plant operations.

Software-defined automation (SDA)

Siemens is pursuing SDA as a strategy to inject IT methodologies and flexibility into industrial environments. At SPS, the company discussed the Simatic AX automation system designed for IT users that integrates native GitHub and Visual Studio Code tooling. The operational foundation for this strategy is the Siemens Industrial Edge platform, which serves as the convergence layer for deploying and centrally managing virtualized workloads. Siemens also announced the availability of 2 new vPLC versions: one that acts as a “bigger PLC” and the other with “a better price point,” but with limited I/Os and memory.

Control hardware and performance scaling

New hardware launches confirmed fundamental performance increases necessary to handle advanced software and connectivity.

- The new Sinamics S220 drive system was introduced as the new “gold standard” for servo drives, featuring a 50% reduction in the size of power electronics and motor modules for market-leading power density. It supports controlling up to 12 axes on one control unit and features safety integrity level 3.

- Siemens also highlighted the rapid adoption of the Simatic S7-1200 G2 for basic automation, noting its increased performance, new kinematics, and support for OPC UA communication.

Cybersecurity and zero-trust architecture

Driven by IT/OT convergence and stricter regulations (like NIS 2), cybersecurity has become a strategic imperative.

- The launch of the SINEC Secure Connect platform introduced formalized zero-trust security principles specifically for OT networks. This platform functions as a “one-stop security platform” for managing communication connections.

- A “security by design” approach ensures products are “hardened ex works,” integrating the latest cyber threat knowledge into continuous product protection.

Digital twin technology and optimization

The focus has shifted from simple visualization to dynamic, physics-informed tools that deliver operational ROI. Showcases included the use of Simcenter technology to implement physics-informed digital twins, as demonstrated by the partnership with BASF Antwerp, yielding tangible results in operational efficiency.

Sustainability and circularity

Sustainability is integrated into product design and service offerings.

- The Siemens EcoTech approach provides transparent, measurable, and auditable sustainability criteria for products, helping customers make environmentally conscious choices.

- New Circular Repair Services were launched, designed to extend the reliable lifetime of automation products, restoring performance and appearance to an almost new standard, thus supporting the transition to a circular economy.

2. Beckhoff Automation

At its SPS 2025 press conference, Germany-based industrial automation company Beckhoff Automation confirmed the renewed positive business sentiment in the industrial automation space after a dismal 2024, when Beckhoff’s revenue dropped by over 30% year-over-year. The company estimates 7% full-year growth for 2025, leading to a projected turnover of €1.25 billion.

While Beckhoff highlighted that its “revolutionary” control cabinet design “MX” has moved into series production and emphasized enhancements to the foundational EtherCAT communication standard, the key theme for the company at SPS 2025 was AI; more specifically, “physical AI,” defining it as the application of AI directly onto the physical world to actively control machinery and axes, such as robots, and help humans achieve more.

“AI is a thought amplifier that allows the human to think thoughts that they could not think before.”

Hans Beckhoff, Founder and Managing Director/Owner of Beckhoff Automation at SPS 2025 (translated from source)

Key themes from Beckhoff Automation at SPS 2025:

Operationalizing industrial AI

Beckhoff showcased how AI is directly integrated into the control layer via TwinCAT software. The TwinCAT CoAgent was a key focus, acting as an AI assistant across the entire automation lifecycle. In operation, it enables service personnel or operators to “speak with the machine,” analyzing machine data to provide solution suggestions for cryptic HMI error messages (e.g., minimizing downtime for errors like “3785”). For engineering, it assists in the workflow by generating PLC code or creating HMI layouts. Furthermore, the TwinCAT 3 Machine Learning Creator (TE3850) now supports AI model creation for signal and time-series analysis, expanding its capabilities beyond its prior focus on image processing.

Physical AI as the next big thing

Beckhoff presented a physical AI concept study. This capability is engineered by integrating Model Context Protocol (MCP) interfaces into the Beckhoff control systems, thereby providing AI agents direct access to machines for command execution. The firm demonstrated this through the ATRO robot, which utilized a large language model (LLM) for visual analysis to interact with objects and autonomously determine actions, such as calculating the next move in a game of chess.

Platform maturity and standardization

The strategic significance of EtherCAT (ECAT), invented by Beckhoff in 2003, was highlighted for its high performance and continued relevance as a global standard for real-time communication. The technology inherently provides strong protection against cybersecurity attacks (“by design”). Beckhoff continues to develop new chips and products for EtherCAT, such as the ET1150 EtherCAT ASIC. Additionally, the company introduced new Atom-based IPCs while planning smaller, low-power Arm-based control panels. The company shared that demand for TwinCAT for Linux remains strong, driven by the need for a Windows alternative and compliance with regulations such as the EU Cyber Resilience Act (CRA).

Next-generation control cabinets

The Beckhoff MX-System represents a potential disruption in how automation hardware is housed. MX is engineered to integrate all necessary components, including IPCs, I/O, and drives, onto a core Baseplate structure. Beckhoff’s strategy is to make industrial automation deployment a structured, project-based effort focused on maximizing efficiency. A company representative noted that the inherent flexibility and ease of assembly define its market appeal, stating that the MX-System is ultimately “Lego” for the control cabinet construction.

3. Rockwell Automation

US-based industrial automation and digital transformation technologies company Rockwell Automation centered its exhibits on the comprehensive theme, “Creating the Future of Industrial Operations.” The company focused on practical strategies for manufacturers to optimize production through the seamless integration of design, operation, and maintenance functionalities. The exhibits emphasized advanced solutions utilizing digital twins, next-generation I/O platforms, and operations powered by industrial AI, all crucial for developing faster, smarter, and more resilient machine architectures.

Key themes from Rockwell Automation at SPS 2025:

Industrial control platforms

The company showcased its new ControlLogix® 5590 PLC as an advancement designed to streamline operations and enable manufacturers to scale systems securely via a unified control platform. Key capabilities from its initial product announcement include integrated functional safety capabilities (SIL2/PLd), increased processing performance and memory capacity, and built-in cybersecurity (based on IEC 62443 standards).

Next-generation I/O

Rockwell Automation showcased its new PointMax™ I/O, a flexible remote input/output system. Its modular architecture is engineered to support scalable and reconfigurable deployments, thereby tackling the increasing complexity of industrial operations.

SDA

From discussions with Rockwell Automation representatives, there are signs that the company is placing a heavier focus on SDA. Despite no official announcements at SPS 2025, the company published a new webpage approximately a week before the fair, discussing SDA and the company’s SDA portfolio.

Industrial AI & co-pilots

The company demonstrated FactoryTalk Analytics LogixAI, a predictive analytics tool that continuously monitors processes to help OT personnel predict product quality issues and protect process integrity. Furthermore, Rockwell Automation announced the integration of an AI co-pilot feature within its Design Studio engineering tool, leveraging NVIDIA technology to explain ladder code and assist with documentation locally on a PC’s GPU.

Digital twin technology

Rockwell showcased its Emulate3D® software, enabling mechanical designs to be digitally modeled and tested. This virtual validation of control systems and machine concepts is used to reduce development time and mitigate risks in fast-paced manufacturing sectors.

4. ABB

Several business units of Switzerland-based electrification and automation company ABB, including its Motion and Electrification units, focused on demonstrating how new products and system solutions meet demands for reliable and efficient plant operations, greater energy efficiency, and enhanced cybersecurity, amidst growing regulatory complexity.

With AI and data intelligence as the primary catalyst for innovation, ABB aimed to show customers how their offerings translate these technological advancements into measurable business value for efficient, safe, and future-ready plants.

Key themes from ABB at SPS 2025:

Energy efficiency and management

ABB showcased solutions for sustainably reducing energy consumption and operational costs. This included systems like ASKI, InSite energy monitoring, and D11/D13 energy meters, which provide precise data for optimal energy management in industrial buildings. The LV Titanium Variable Speed Motors were highlighted as an innovative, plug-and-play platform combining an advanced drive module with a highly efficient motor to significantly reduce energy consumption and emissions.

Decarbonization and circularity

The company presented technologies supporting the transition toward climate neutrality, incorporating electrification, renewable energies, energy storage, and smart grid integration. The company introduced Solid State Circuit Breaker SACE Infinitus, designed for sustainable DC networks, offering a lifespan 100 times longer than conventional breakers and enabling up to a 70% reduction in energy losses across the value chain. ABB also featured the DCT880 Thyristor Power Controller for CO₂-neutral electric heating and noted its role as a technology partner in green hydrogen production via electrolysis.

Operationalizing industrial AI

ABB emphasized leveraging AI to analyze data, automate processes, and increase productivity. The company is directing AI capabilities toward high-return applications, such as energy efficiency, by integrating an AI-powered 3D visualization solution from Germany-based digital twin platform company Cloudworx, the winner of the ABB Startup Challenge 2025. This technology helps OEMs simplify the selection, commissioning, and troubleshooting of motors and variable-speed drives.

Advanced industrial controls and safety

Innovations in core control hardware reflected the need for integrated intelligence and enhanced protection. The SACE Emax3 air circuit breaker was featured, incorporating integrated sensors and intelligent algorithms to enable predictive maintenance while also holding cybersecurity certification according to Security Level 2. The ACS380-E drive was presented for machine integration, offering fast commissioning, diverse communication options, and safety features that comply with upcoming standards.

Data center infrastructure presence

Beyond new products, ABB reaffirmed its strong market position, providing essential components across many channels, leading to ABB components being utilized in over a quarter of the data center market (according to ABB). This portfolio includes electrical distribution, controllers, transformers, motors, drives, and components for liquid cooling systems, alongside data center automation services.

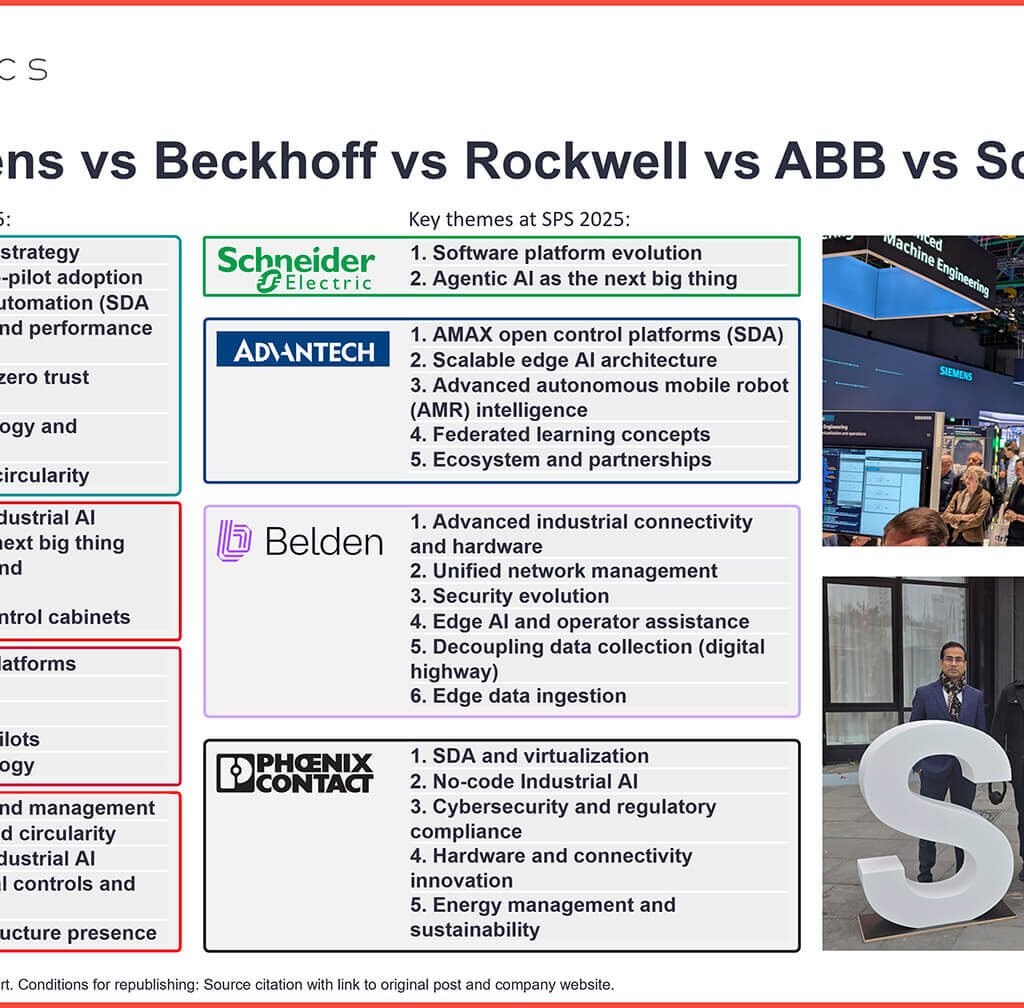

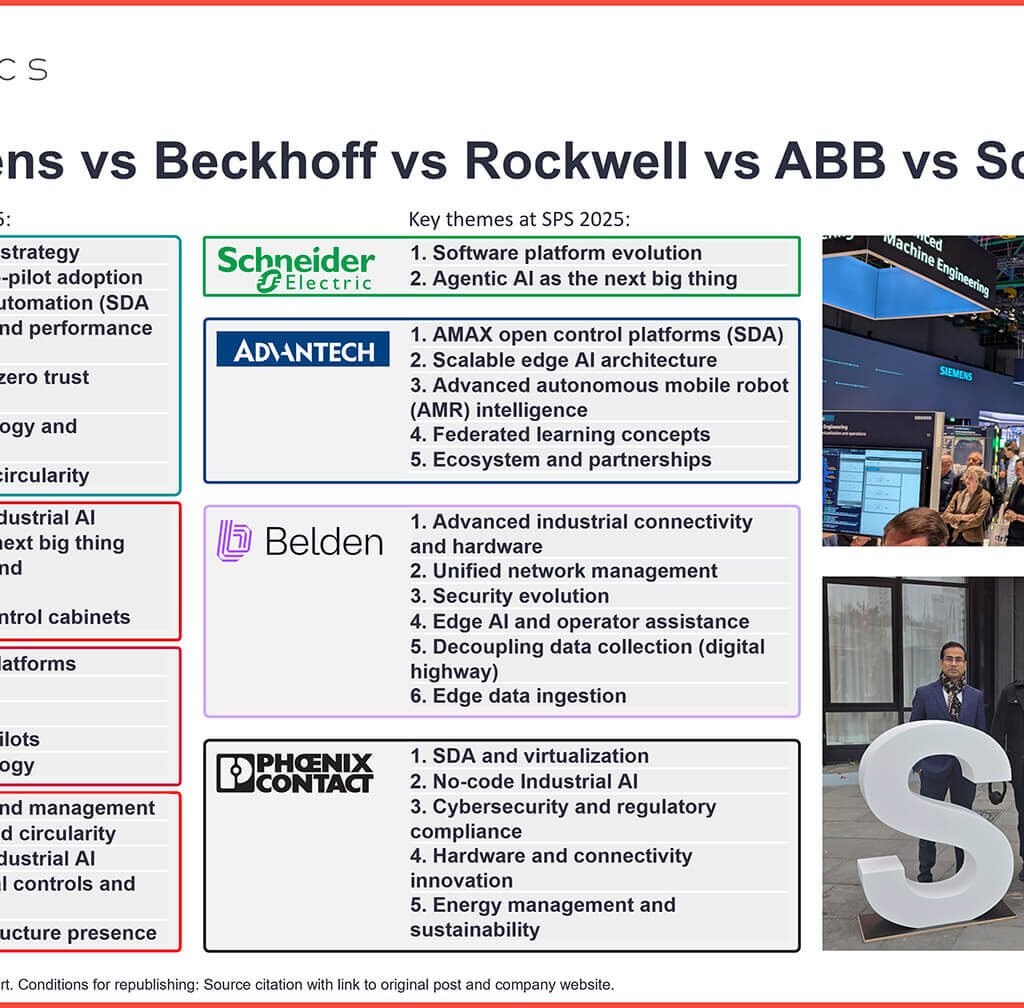

5. Schneider Electric

The core of France-based automation and energy management company Schneider Electric’s showcase centered on open, software-defined automation, emphasizing interoperable architectures meant to reduce engineering complexity and improve system performance, with “Industrial Automazing” as the new marketing campaign. The company also demonstrated how agentic AI promises significant productivity gains, particularly addressing the pervasive issue of skilled workforce shortages in automation.

Key themes from Schneider Electric at SPS 2025:

Software platform evolution

The EcoStruxure suite was highlighted, with EcoStruxure Automation Expert (EAE) serving as an open and interoperable orchestration layer. Aveva Connect acts as a cloud-based SaaS historian. The recent introduction of Aveva Advanced Analytics (a no-code, cloud-native SaaS solution) and the Asset Information Manager (for managing engineering and asset data) emphasize a strategic shift toward cloud analytics and a single source of truth for assets. Schneider also noted increased support for the popular Profinet protocol.

Agentic AI as the next big thing

Schneider Electric is positioning agentic AI as a disruptive evolution past traditional GenAI, emphasizing its core capability to act and execute tasks autonomously within industrial automation environments, rather than just assisting in content creation. Integrated within the EcoStruxure Automation Platform, the SPS showcase is designed to automate the entire system development lifecycle based on user specifications, handling everything from analyzing documentation and creating asset instances (sensors or actuators) to building the digital twin and generating the control application utilizing EcoStruxure Automation Expert. The agent is capable of deploying the application, performing functions like unit testing and high-fidelity simulation, all while keeping the user “in the loop” to validate and approve proposed changes. Strategically, this initiative is a direct response to the industry shortage of automation users, with a representative at the booth seeing a potential of up to 70% efficiency gains by automating processes previously performed manually.

6. Advantech

Taiwan-based IoT intelligent systems and automation platform company Advantech centered its exhibition on the transition from isolated products to operationalized intelligence within an open, resilient ecosystem. The company introduced a strategic direction emphasizing open architecture, scalable edge AI, SDA control, and the WISE-Edge Developer Architecture for efficient edge orchestration. These efforts are intended to accelerate IT/OT convergence and align with stringent emerging cybersecurity mandates, such as the CRA.

“AI and edge computing are rapidly shifting from pilot concepts to the core of daily operations. Customers are no longer satisfied with isolated products. They expect partners who understand both IT and OT, can guide them through cybersecurity and regulatory complexities, and provide scalable edge platforms that deliver real-time intelligence across entire facilities.”

Chingpo Lin, VP for Global IoT Automation, Advantech

Key themes from Advantech at SPS 2025:

AMAX open control platforms (SDA)

Advantech showcased its AMAX IoT Control Platforms (announced in July 2025), which the company says address the scaling constraints of legacy PLC and IPC systems when faced with intensive vision, motion, and sensing workloads. AMAX platforms are based on an open industrial PC architecture, supporting soft PLCs, real-time operating systems, and virtualized controllers on a unified platform.

Scalable edge AI architecture

Advantech is positioning edge AI for critical, real-time applications by providing a comprehensive developer stack that enables the easy deployment of containerized models, device management, and time-series data collection from the field. The approach caters to customer preference for running major AI training systems at the edge, sending only metadata to the cloud.

Advanced autonomous mobile robot (AMR) intelligence

Demonstrations featured AMR intelligence built on the powerful NVIDIA Jetson AGX Orin platform, showcasing 360° perception and multi-sensor fusion capabilities. This focus aims to enable AMR deployments to scale rapidly from pilot trials to large-scale industrial operations. One notable approach is for AMRs to initiate self-training as they recharge, based on data collected on the shop floor, making them smarter and avoiding the need to expend further training resources.

Federated learning concepts

To address data privacy concerns, particularly in diverse or competitive multi-robot environments, Advantech is using federated learning, or aggregated learning, where only AI models, rather than sensitive raw data, are shared and aggregated to refine overall model accuracy.

Ecosystem and partnerships

Advantech emphasizes an open, vendor-agnostic ecosystem, highlighting partnerships with technology leaders such as NVIDIA, Intel, AWS, and Qualcomm to drive innovation. The company showcased co-developed solutions with multiple partners, including Bosch Rexroth, SALZ Automation, and Xentara.

7. Belden

US-based industrial connectivity solutions company Belden demonstrated solutions aimed at enhancing network visibility, streamlining management, and establishing intrinsically reliable data architectures at the industrial edge. The company leveraged the exhibition to confirm its strategic focus on bridging the gap between networking hardware and centralized IT orchestration tools.

Key themes from Belden at SPS 2025:

Advanced industrial connectivity and hardware

Belden launched its first Industrial Access Point for deterministic, low-latency Wi-Fi 7 with dual-concurrent 5 GHz/6 GHz functionality, targeting robotics, logistics, and automation applications. The company also introduced its Single Pair Ethernet (SPE) REVConnect FlexPlug, intended to simplify SPE installations for smart building applications.

Unified network management

The Belden Horizon platform continues to serve as a unified network management tool, defining a KPI focused on network effectiveness. The platform provides capabilities for secure remote access to a single management gateway via the cloud, allowing connectivity in layer two to the local network.

Security evolution

While the Belden Horizon platform includes asset inventory valuable for OT security, a separate security solution focused on endpoint identification and access control (defining correct VLANs) is currently standalone but is slated to become one of the services offered on the Horizon platform. Belden announced that its IAF-240 Industrial Firewall now integrates with Hirschmann Industrial HiVision Network Management Software and offers an optional Intrusion Prevention Pro module. Additionally, the recently updated macmon NAC (version 6.4.0) introduced new Ethernet/IP capabilities for OT environments and EAP-FAST for enhanced 802.1X authentication.

Edge AI and operator assistance

Belden’s AI focus is on networking, as evidenced by the “digital coworker” proof of concept. This AI model, which uses a raw model like Tropic Load 4.5 fine-tuned for cost efficiency, acts as an expert assistant for operators, providing advice on networking issues (such as MRP ring operation) via a chat interface. This product is currently internal but is being validated for eventual commercial release.

Decoupling data collection (digital highway)

One notable demonstration involved the “digital highway” approach, where an edge device collects data straight from sensors (using protocols like PROFINET) and sends it to the cloud for analytics. This process runs in parallel to the actual control system without interruption, addressing the complexity and costly validation required when altering control systems, particularly in industries like pharmaceuticals.

Edge data ingestion

Belden detailed its edge computing capabilities, running its Belden Horizon Data Operations (BHDO) data ingestion software on its ARM and Intel CPU-based edge devices. BHDO connects devices via various protocols, processes data into JSON packets via an internal broker, and makes the information available to applications, such as Node-RED or analytics applications. Data can be output via an OPC UA server or connected to various higher platforms using database-agnostic connectors (e.g., SQL, MongoDB, and InfluxDB).

8. Phoenix Contact

Germany-based industrial connectivity and automation company Phoenix Contact’s exhibition served to show the commercial and technical maturity of its core automation architecture, PLCnext Technology. The company focused heavily on addressing the accelerating convergence of IT and OT environments, prioritizing virtualization, intrinsic security, and openness as foundational principles.

“Opens means that we redesigned an entirely new system. It was not the question of building a new next-generation PLC but creating an entire ecosystem. We followed several design principles, and openness by design was beside security by design, a very important issue.”

Dr. Tobias Frank, Vice President of Automation Systems at Phoenix Contact (source)

Key themes from Phoenix Contact at SPS 2025:

SDA and virtualization

Phoenix Contact prominently showcased the Virtual PLCnext Control as a scalable, hardware-independent core of its open automation ecosystem. This controller is packaged as an Open Container Initiative (OCI) container, enabling deployment on standard Linux-based IPCs or edge servers, and supporting multiple simultaneous instances for flexible, real-time control architectures. The company introduced 3 new versions (1000, 2000, and 3000 series) to its portfolio and highlighted ongoing development into system redundancy via Kubernetes. This technology is actively being deployed in demanding environments such as electrical power and monitoring systems (EPMS) for data centers and for controlling renewable energy grids.

No-code Industrial AI

The company introduced the MLnext app, an AI solution designed to support industrial processes without requiring expertise in data science. The use of real-time data is geared toward applications like predictive maintenance and equipment monitoring.

Cybersecurity and regulatory compliance

Cybersecurity was identified as the most prominent customer challenge currently facing the industry. Phoenix Contact is ensuring its products are ready for impending European regulations, including the EU CRA and the NIS2 directive. The PLCnext Technology platform is designed with security and functional safety integrated, following the IEC 62443 standard. At the fair, the company announced that its managed switches received IEC 62443 certification.

Hardware and connectivity innovation

Phoenix Contact showcased its Push-X technology, a tool-free conductor connector designed to allow flexible or rigid conductors to be connected quickly. The company also presented its new Wi-Fi 6 and Wi-Fi 6E access points, scheduled for release in Q1 2026.

Energy management and sustainability

The company is strategically prioritizing support for DC grids, viewing it as a move toward higher efficiency and sustainability that can result in energy savings of up to 8%. Phoenix Contact is actively involved in supplying components for Power-to-X applications, supporting decarbonization efforts. Furthermore, the company highlighted its remote relay systems as solutions to provide flexible and safe signal processing independent of specific controllers. The company is also developing components for Single Pair Ethernet, applicable across various markets, including building automation and traffic.

Disclosure

Companies mentioned in this article—along with their products—are used as examples to showcase market developments. No company paid or received preferential treatment in this article, and it is at the discretion of the analyst to select which examples are used. IoT Analytics makes efforts to vary the companies and products mentioned to help shine attention on the numerous IoT and related technology market players.

It is worth noting that IoT Analytics may have commercial relationships with some companies mentioned in its articles, as some companies license IoT Analytics market research. However, for confidentiality, IoT Analytics cannot disclose individual relationships. Please contact compliance@iot-analytics.com for any questions or concerns on this front.

More information and further reading

Related publications

You may also be interested in the following reports:

- MES Market Report 2025-2031

- Data Center Equipment & Infrastructure Market Report 2025-2030

- Digitalization of Industrial Drives – Adoption Report 2025

- Digital & AI in Industrial Robotics Insights Report 2025

- Industrial AI Market Report 2025-2030

Related articles

- Data center infrastructure market: AI-driven CapEx pushing IT and facility equipment spending toward $1 trillion by 2030

- Digitalizing industrial motors & drives: 4 upgrades enabling the next era of efficiency

- Industrial AI market: 10 insights on how AI is transforming manufacturing

- Smart manufacturing check-in: 6 learnings from ongoing digital transformation initiatives

Sign up for our research newsletter and follow us on LinkedIn to stay up-to-date on the latest trends shaping the IoT markets. For complete enterprise IoT coverage with access to all of IoT Analytics’ paid content & reports, including dedicated analyst time, check out the Enterprise subscription.