In short

- IoT edge computing resources are becoming increasingly intelligent

- There are 7 key characteristics that make modern edge computing more intelligent (including open architectures, data pre-processing, distributed applications)

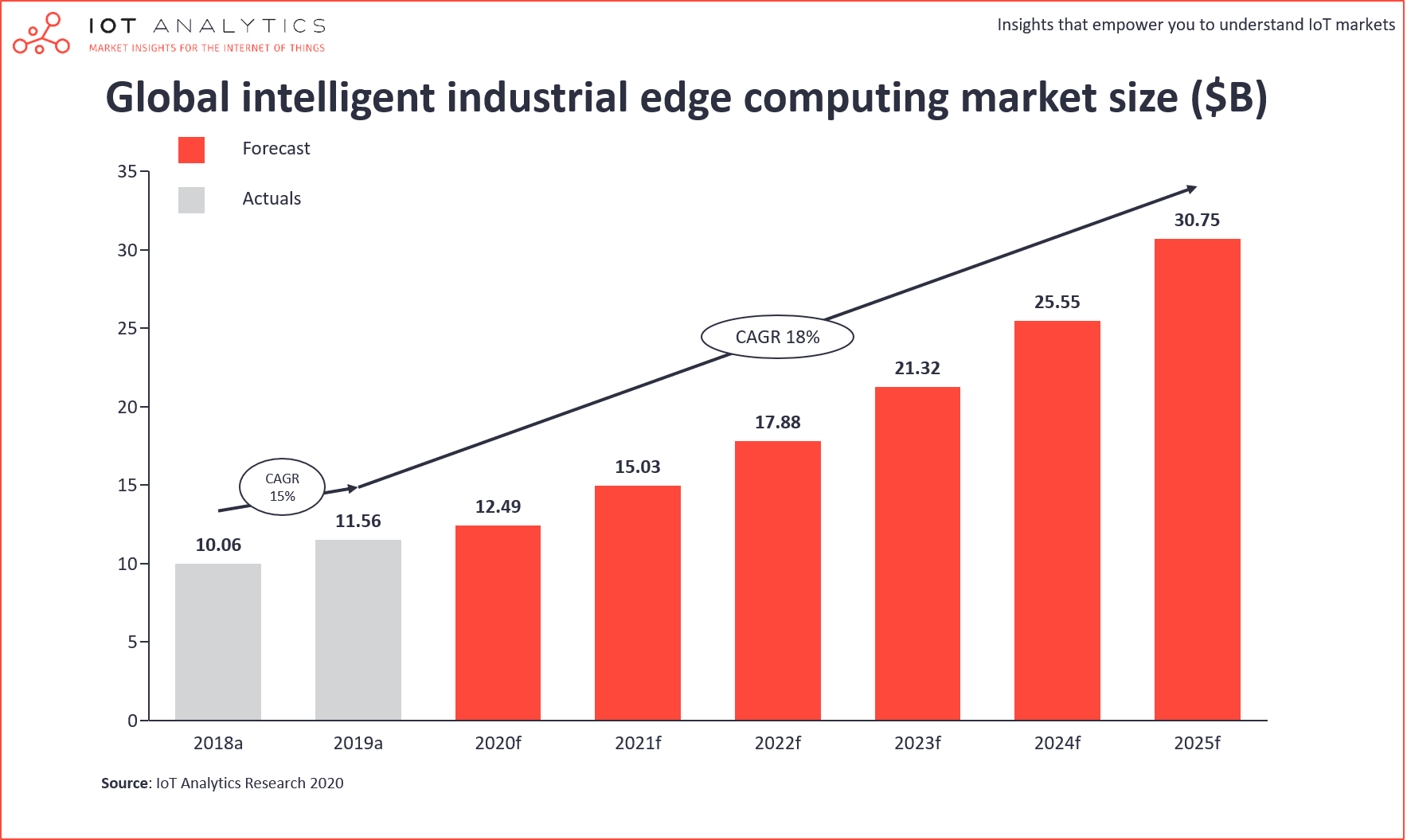

- The intelligent industrial edge computing market is estimated to reach $30.8B by 2025, up from $11.6B in 2020 (see new 248-page report)

Why it matters

- IT/OT architectures are evolving quickly

- Organizations that manage physical assets can reap tremendous cost savings and unlock new opportunities by switching to modern, intelligent edge computing architectures

Why has the interest in “edge computing” become so widespread in recent years?

The primary reason why the edge has become so popular in recent years is because the “edge” as we know it is becoming increasingly intelligent. This “intelligent edge” opens up a whole new set of opportunities for software applications and disrupts some of today’s edge to cloud architectures on all 6 layers of the edge. This according to IoT Analytics’ latest research on Industrial IoT edge computing.

According to the report, intelligent edge compute resources are replacing “dumb” legacy edge compute resources at an increasing pace. The former makes up a small portion of the market today but is expected to grow much faster than the overall market and thus gain share on the latter. The hype about edge computing is warranted because the replacement of “dumb” edge computing with intelligent edge computing has major implications for companies in all sectors, from consumer electronics and machinery OEMs to manufacturing facilities and oil and gas wells.

Benefits of switching from “dumb” to “intelligent” edge computing architectures include an increase in system flexibility, functionality, scalability and in many cases a dramatic reduction in costs; one of the companies that was analyzed for the edge computing research realized a 92% reduction in industrial automation costs by switching to intelligent edge hardware.

Where is the edge?

A lot of great work has been done in recent years to define and explain “the edge”. Cisco was an early thought leader in the space, conceptualizing the term “fog computing” and developing IoT solutions designed to run there. LF Edge (an umbrella organization under the Linux Foundation) publishes an annual “State of the Edge” report which provides a modern, comprehensive and vendor-neutral definition of the edge. While these broad definitions are certainly helpful, the fact is that the edge is often “in the eye of the beholder”.

For instance, a telecommunications (telco) provider may view the edge as the micro datacenter located at the base of a 5G cell tower (often referred to as “Mobile Edge Computing” or MEC), while a manufacturing end user may view the edge as the vision sensor at the end of the assembly line. The definitions are different because the goal / purpose of hosting workloads at the edge is different: the telco provider is trying to optimize data consumption (i.e. performance issues associated with consumers of the data), while the manufacturing end user is trying to optimize data generation (i.e. performance issues associated with transmitting and analyzing the data).

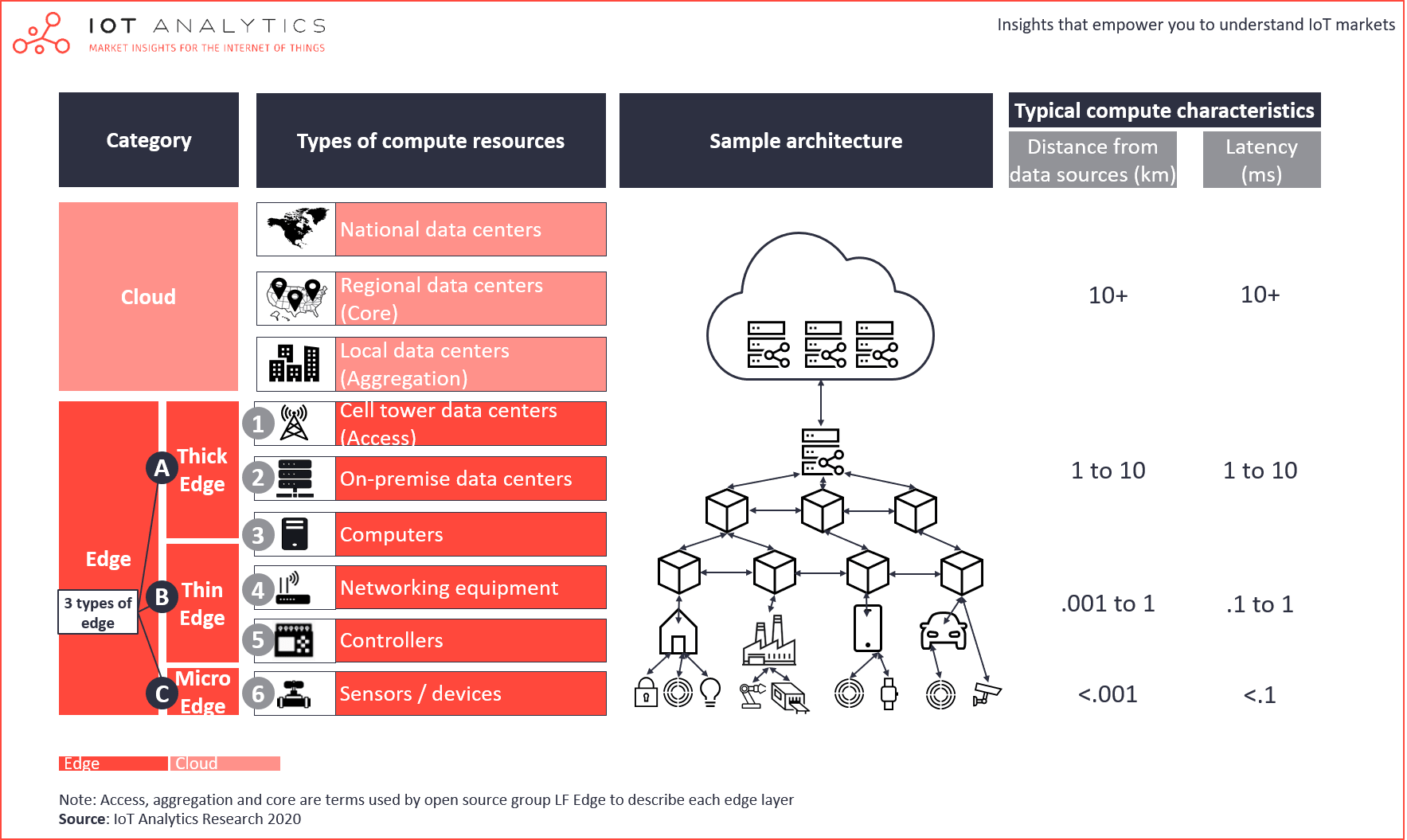

IoT Analytics defines edge computing as a term used to describe intelligent computational resources located close to the source of data consumption or generation. “Close” is a relative term and is more of a continuum than a static place. It is measured by the physical distance of a compute resource from its data source. There are 3 types of edges, and each of them is home to 1 or more types of compute resources:

The three types of edge

A. Thick edge

The thick edge describes compute resources (typically located within a data center) which are equipped with components designed to handle compute intensive tasks / workloads (e.g., high-end CPUs, GPUs, FGPAs, etc.) such as data storage and analysis. There are two types of compute resources located at the “thick” edge, which is typically located 100m to ~40 km from the data source:

- Cell tower data centers, which are rack-based compute resources located at the base of cell towers

- On prem data centers, which are rack-based compute resources located at the same physical location as the sensors generating the data

B. Thin edge

Thin edge describes the intelligent controllers, networking equipment and computers that aggregate data from the sensors / devices generating data. “Thin edge” compute resources are typically equipped with middle-tier processors (e.g., Intel i-series, Atom, Arm M7+, etc.) and sometimes include AI components such as GPUs or ASICs. There are 3 types of compute resources located at the “thin” edge, which is typically located at 1m to 1km from the data source.”:

- Computers, which are generic compute resources located outside of the data center (e.g., industrial PCs, Panel PCs, etc.)

- Networking equipment, which are intelligent routers, switches, gateways and other communications hardware primarily used for connecting other types of compute resources.

- Controllers, which are intelligent PLCs, RTUs, DCS and other related hardware primarily used for controlling processes.

C. Micro edge

Micro edge describes the intelligent sensors / devices that generate data. “Micro edge” devices are typically equipped with low-end processors (e.g., Arm Cortex M3) due to constraints related to costs and power consumption. Since compute resources located at the “micro edge” are the data generating devices themselves, the distance from the compute resource is essentially zero. One type of compute resource is found at the micro edge:

- Sensors / devices, which are physical pieces of hardware that generate data and / or actuate physical objects. They are located at the very farthest edge in any architecture.

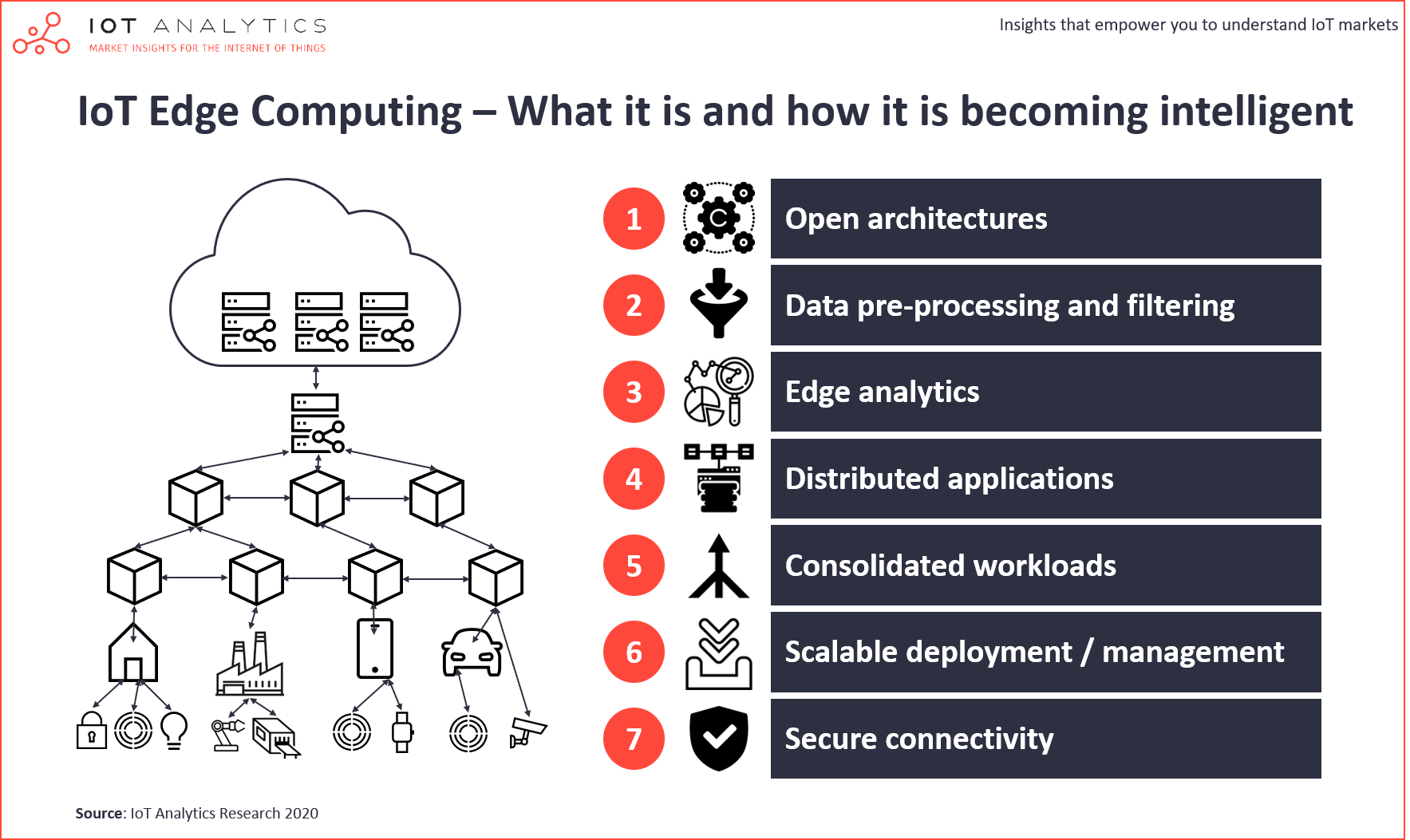

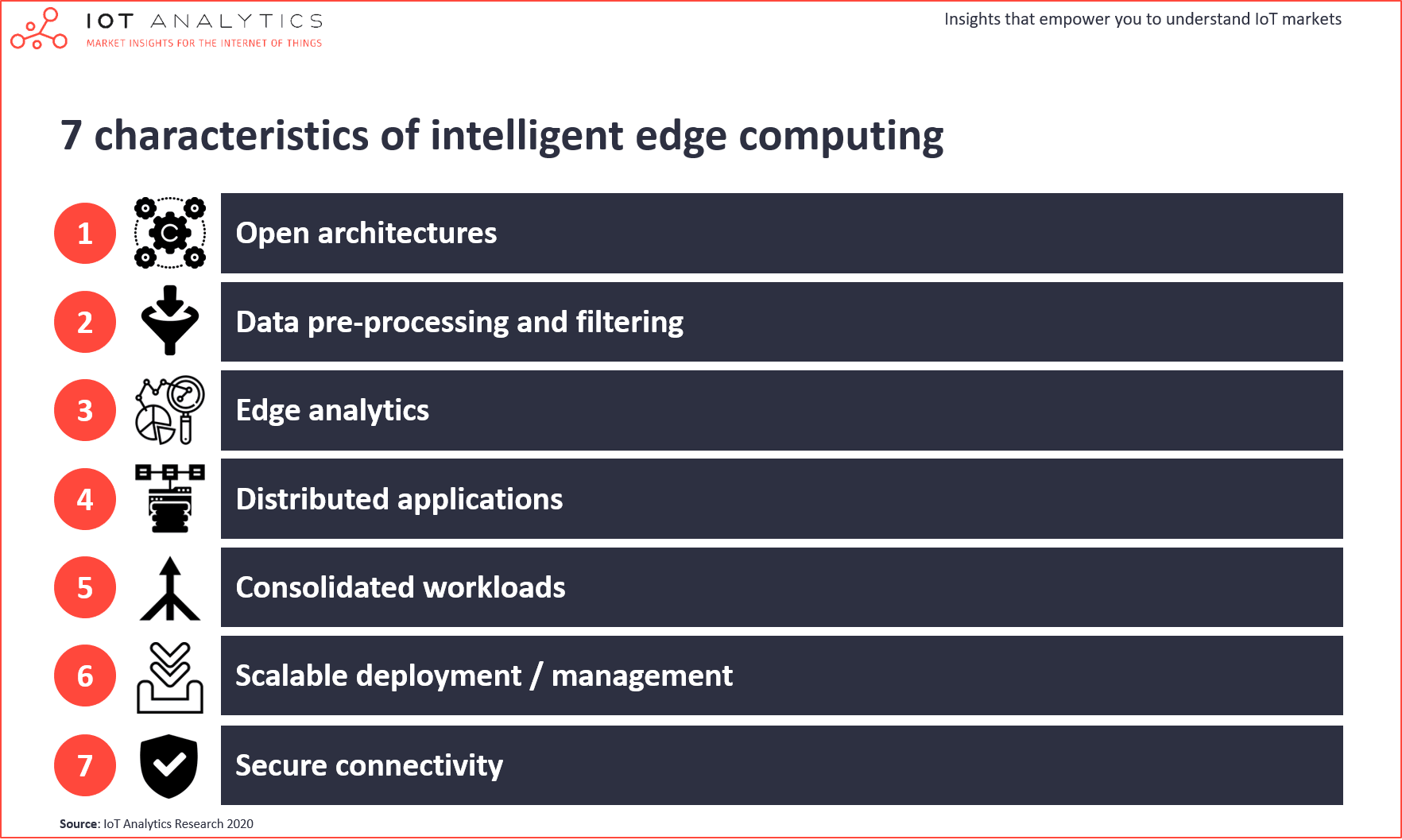

Modern intelligent edge computing architectures are the driving force behind the move to more edge computing and the value-creating use cases associated with the edge. 7 key characteristics distinguish modern intelligent edge computing from legacy systems:

7 characteristics of intelligent edge computing

1. Open architectures

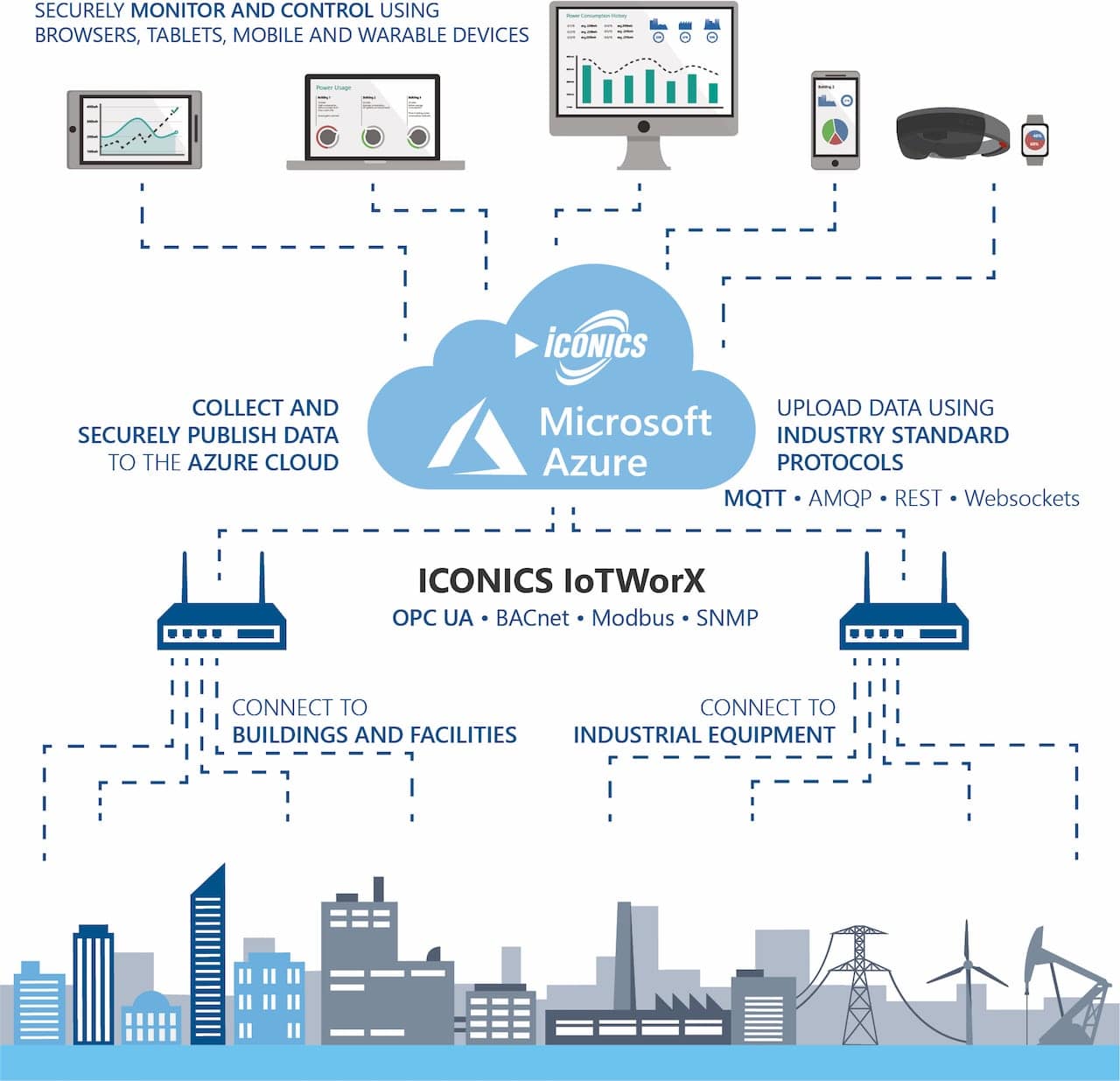

Proprietary protocols and closed architectures have been commonplace in edge environments for decades. However, these have often proven to lead to high integration and switching costs as vendors lock-in their customers. Modern, intelligent edge computing resources deploy open architectures that leverage standardized protocols (e.g., OPC UA, MQTT) and semantic data structures (e.g., Sparkplug) that reduce integration costs and increase vendor interoperability. An example for open protocols is Iconics IoTWorX, an edge application which supports open, vendor-neutral protocols such as OPC UA and MQTT, among others.

2. Data pre-processing and filtering

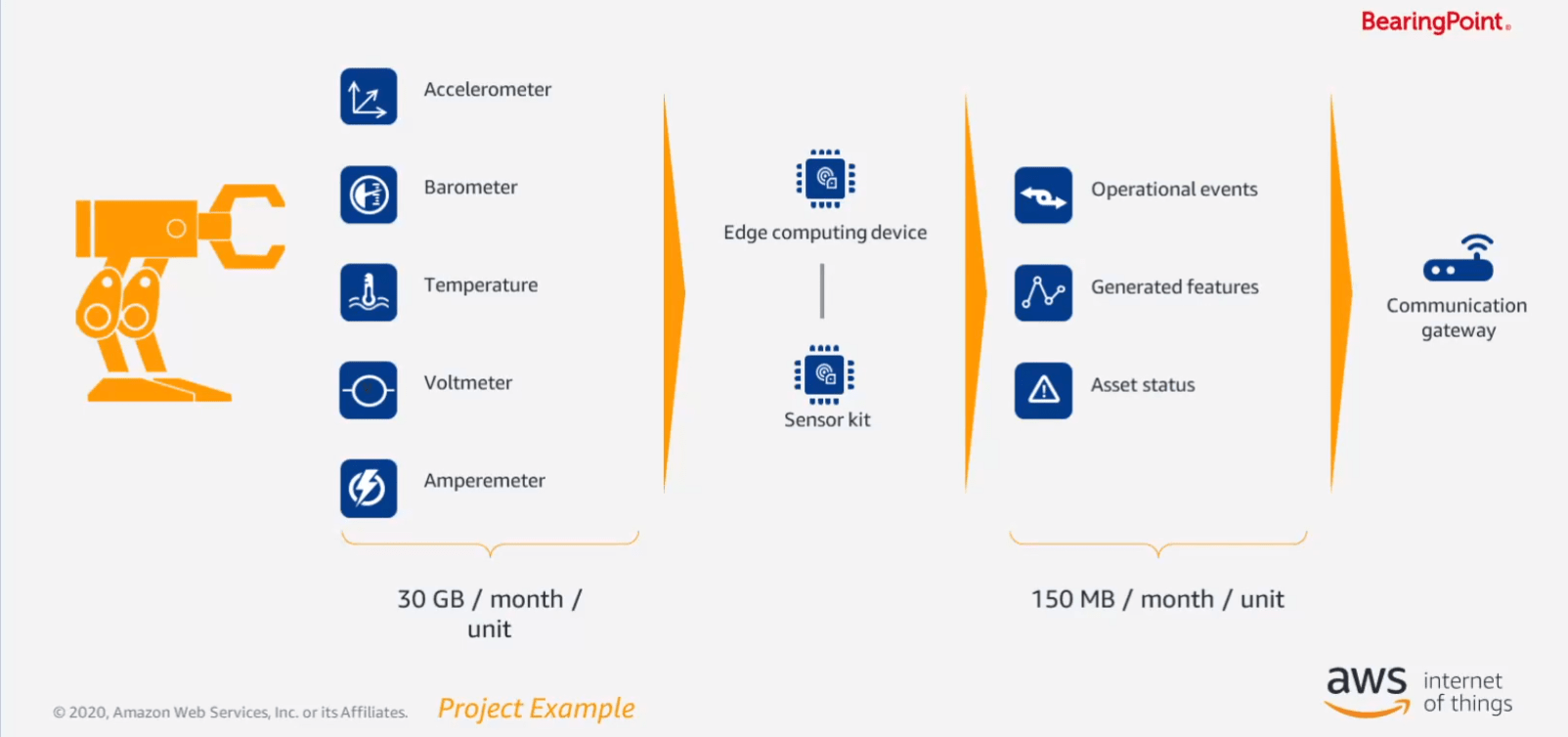

Transmitting and storing data generated by legacy edge computing resources in the cloud can be very expensive and inefficient. Legacy architectures often rely on poll / response setups in which a remote server requests a value from the “dumb” edge computing resource on a time-interval, regardless of whether or not the value has changed. Intelligent edge computing resources can pre-process data at the edge and only send relevant information to the cloud, which reduces data transmission and storage costs. An example of data pre-processing and filtering is an intelligent edge computing device running an edge agent that pre-processes data at the edge before sending it to the cloud, thus reducing bandwidth costs (see AWS project example).

3. Edge analytics

Most legacy edge computing resources have limited processing power and can only perform one specific task / function (e.g., sensors ingest data, controllers control processes, etc.). Intelligent edge computing resources typically have more powerful processing capabilities designed to analyze data at the edge. These edge analytics applications enable new use cases that rely on low-latency and high data throughput. Octonion, for example, uses ARM-based intelligent sensors to create collaborative learning networks at the edge. The networks facilitate the sharing of knowledge between intelligent edge sensors and allow end users to build predictive maintenance solutions based on advanced anomaly detection algorithms.

4. Distributed applications

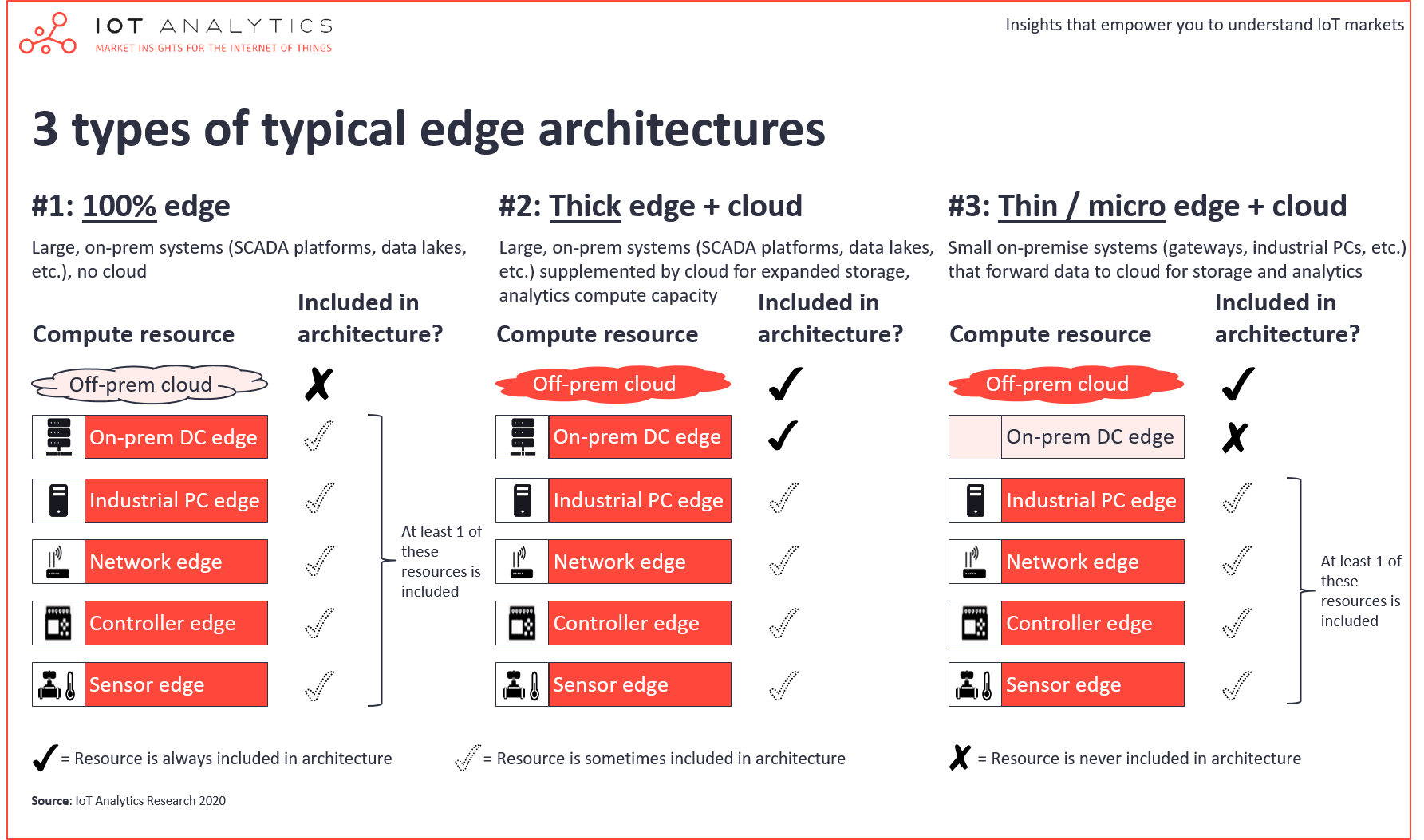

The applications that run on legacy edge computing devices are often tightly coupled to the hardware on which they run. Intelligent edge computing resources de-couple applications from the underlying hardware and enable flexible architectures in which applications can move from one intelligent compute resource to another. This de-coupling enables applications to move both vertically (e.g., from the intelligent edge computing resource to the cloud) and horizontally (e.g., from one intelligent edge computing resource to another) as needed. There are 3 types of edge architectures in which edge applications are deployed:

- 100% edge architectures. These architectures do not include any off-premises compute resources (i.e. all compute resources are on-premise). 100% edge architectures are often used by organizations that do not send data to the cloud for security / privacy reasons (e.g., defense suppliers, pharmaceutical companies) and / or large organizations that have already invested heavily in on-premise computing infrastructure.

- Thick edge + cloud architectures. These architectures always include an on-prem data center + cloud compute resources and optionally include other edge compute resources. Thick edge + cloud architectures are often found in large organizations that have invested in on-prem data centers but leverage the cloud to aggregate and analyze data from multiple facilities.

- Thin / micro edge + cloud architectures. These architectures always include cloud compute resources connected to one or more smaller (i.e. not on-prem data centers) edge compute resources. Thin / micro edge architectures are often used to collect data from remote assets that are not part of existing plant network.

Modern edge applications need to be architected so that they can run on any of the 3 edge architectures. Lightweight edge “agents” and containerized applications in general are two examples of modern edge applications which enable more flexibility when designing edge architectures.

5. Consolidated workloads

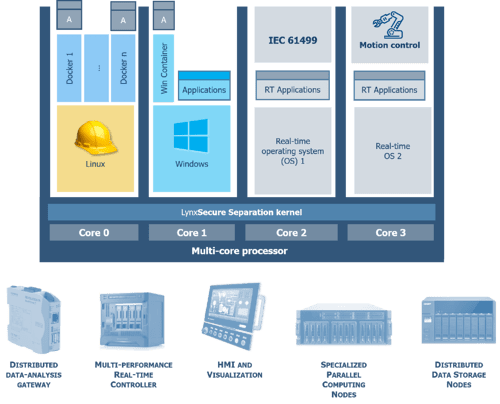

Most “dumb” edge computing resources run proprietary applications on top of proprietary RTOSs (real-time operating system) which are installed directly on the compute resource itself. Intelligent edge computing resources are often equipped with hypervisors which abstract the operating system and application from the underlying hardware. This enables an intelligent edge computing resource to run multiple operating systems and applications on a single edge device. This leads to workload consolidation, which reduces the physical footprint of the compute resources required at the edge and can result in lower COGS (cost of goods sold) for device or equipment manufacturers that previously relied on multiple physical compute resources. The example below shows how a hypervisor is used to run multiple operating systems (Linux, Windows, RTOS) and containerized applications (Docker 1, Win Container) all within a single piece of hardware.

6. Scalable deployment / management

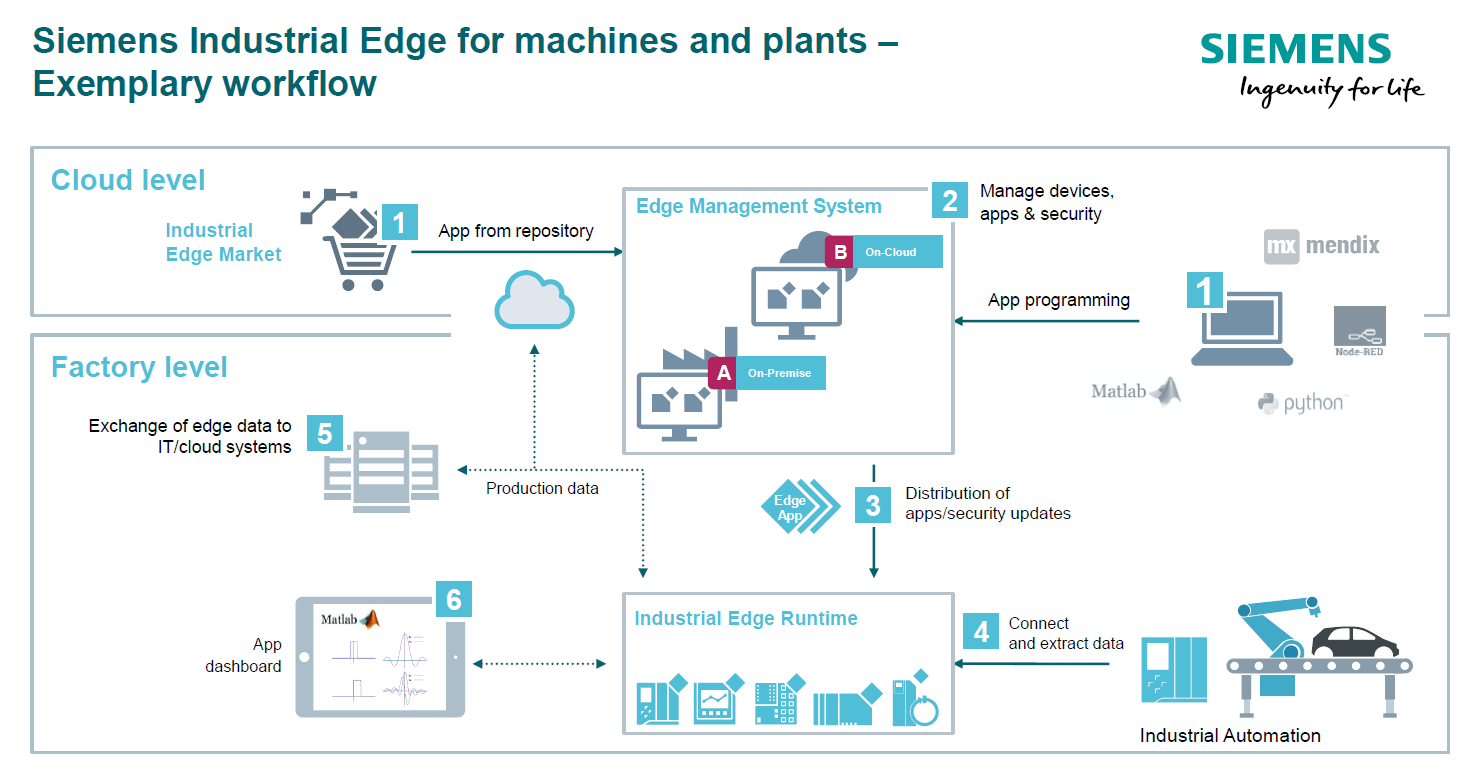

Legacy compute resources often use serial (often proprietary) communication protocols which are difficult to update and manage at scale. Intelligent edge computing resources are securely connected to local or wide area networks (LAN, WAN) and can thus be easily deployed and managed from a central location. Edge management platforms are increasingly being used to handle the administrative tasks associated with large scale deployments. An example of an edge management platform is Siemens’ Industrial Edge Management System, which is used for deploying and managing workloads on Siemens’ intelligent edge compute resources.

7. Secure connectivity

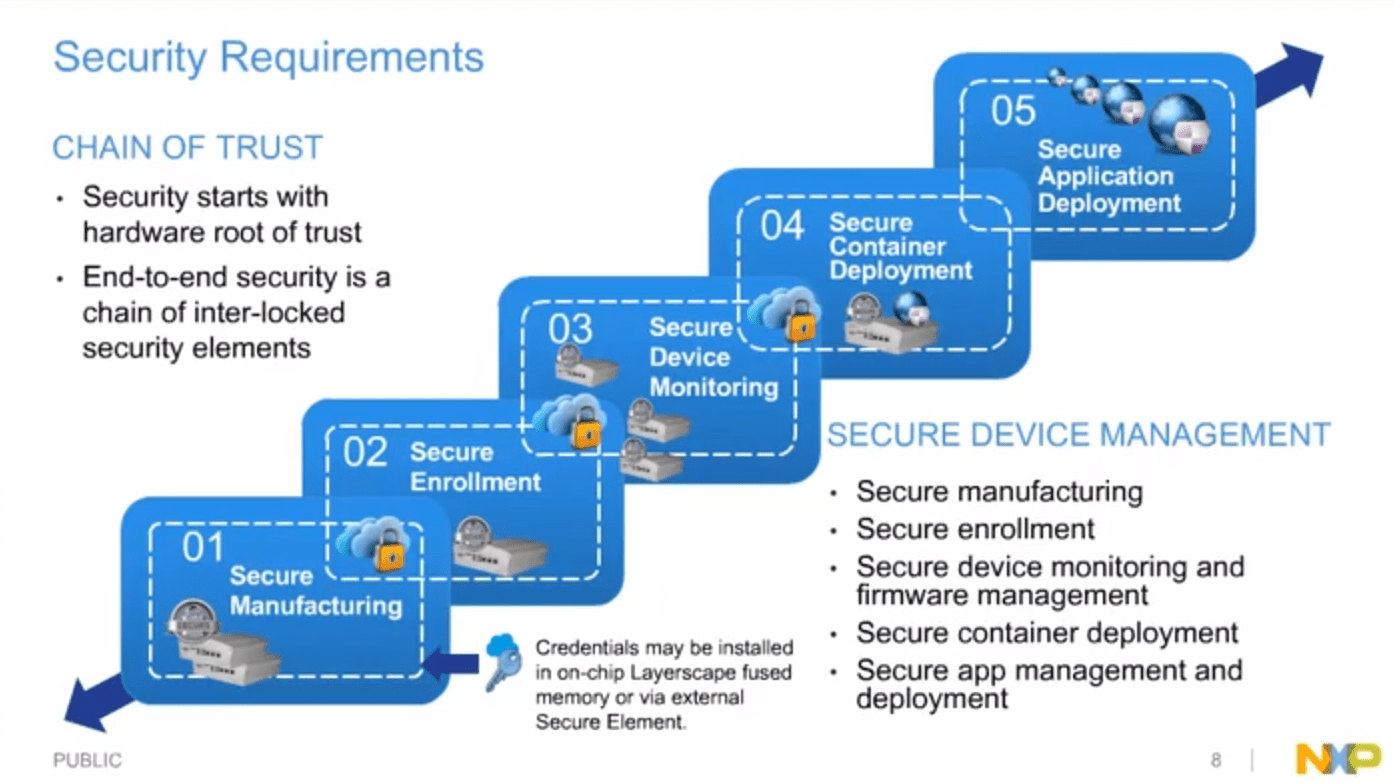

“Security by obscurity” is a common practice for securing legacy compute devices. These legacy devices often have proprietary communication protocols and serial networking interfaces, which do add a layer of “security by obscurity”; however, this type of security comes at a cost of much higher management and integration costs. Advancements in cybersecurity technology (e.g., hardware security modules [ HSMs]) are making it easier and safer than ever to securely connect intelligent devices. Different levels of security can be provided throughout the product lifecycle depending on the specific needs of the application. NXP’s end-to-end security solution, for example, begins at the device manufacturing level and spans all the to the deployment of applications on the connected edge devices.

The market for intelligent edge computing

The focus of our latest report on industrial edge computing explores the intelligent industrial edge in much greater depth. The report focusses on edge computing at industrial sites such as manufacturing facilities, power plants, etc. According to our findings, intelligent industrial edge computing will make up an increasingly large share of the overall industrial automation market, growing from ~7% of the overall market in 2019 to ~16% by 2025. The total market for intelligent industrial edge computing (hardware, software, services) reached $11.6B in 2019 and is expected to increase to $30.8B by 2025.

More information and further reading

Are you interested in learning more about industrial edge computing?

The Industrial Edge Computing Market Report 2020-2025 is part of IoT Analytics’ ongoing coverage of Industrial IoT and Industry 4.0 topics (Industrial IoT Research Workstream). The information presented in the report is based on extensive primary and secondary research, including 30+ interviews with industrial edge computing experts and end users conducted between December 2019 and October 2020. The document includes a definition of industrial edge computing, market projections, adoption drivers, case study analysis, key trends & challenges, and insights from relevant surveys.

This report provides answers to the following questions (among others):

- What is Industrial Edge Computing?

- What are the different types of industrial edges?

- What is the difference between traditional industrial hardware and intelligent edge hardware?

- How big is the industrial edge computing market? Market segments include:

- Hardware

- Intelligent sensors

- Intelligent controllers

- Intelligent networking equipment

- Industrial PCs

- On-prem data centers

- Software

- Edge applications (e.g. analytics, control, data ingestion, storage and visualization)

- Edge platforms

- Hardware

- Which industrial edge computing use cases are gaining the most traction?

- Who are the leading industrial edge computing vendors and what are their offerings?

- What are the key trends and challenges associated with industrial edge computing?

A sample of the report can be downloaded here:

Are you interested in continued IoT coverage and updates?

Subscribe to our newsletter and follow us on LinkedIn and Twitter to stay up-to-date on the latest trends shaping the IoT markets. For complete enterprise IoT coverage with access to all of IoT Analytics’ paid content & reports including dedicated analyst time check out Enterprise subscription.