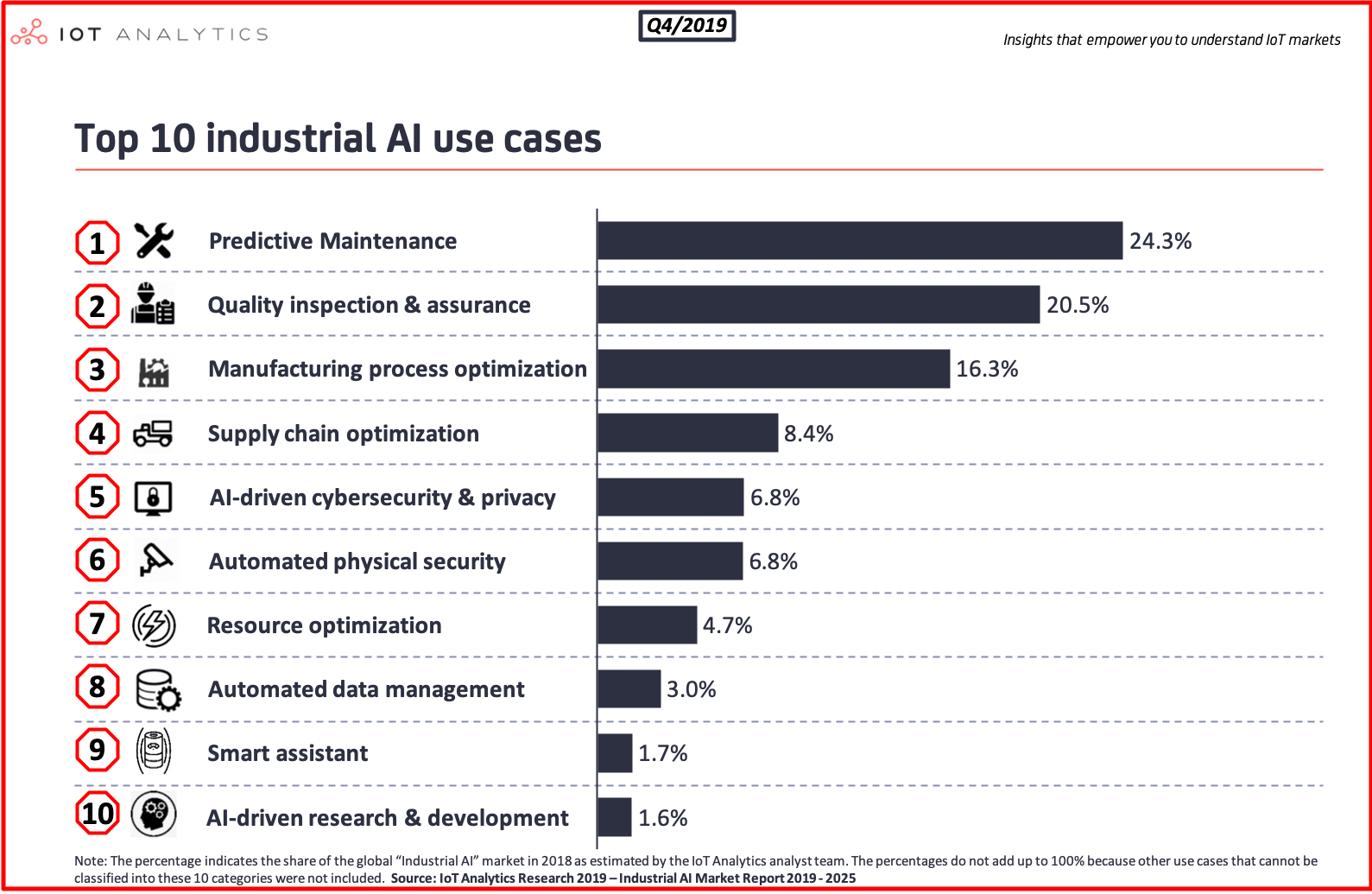

IoT Analytics’ recently published the Industrial AI Market Report 2020-2025. As part of the research, the analyst team identified a total of 33 different use cases that employ Artificial Intelligence tools and techniques on (predominantly) IoT-connected data sources and assets of industrial enterprises. These 33 industrial AI use cases have been grouped into 10 broader use case categories which make up the majority of the almost $15B Industrial AI market in 2019.

The top 10 ranked by size are:

#1: Predictive maintenance

The largest use case for industrial AI is “Predictive Maintenance” (estimated to make up over 24% of the total market in 2018). Predictive Maintenance makes use of advanced analytics (e.g., Machine Learning) to determine the condition of a single asset or an entire set of assets (e.g., a factory).

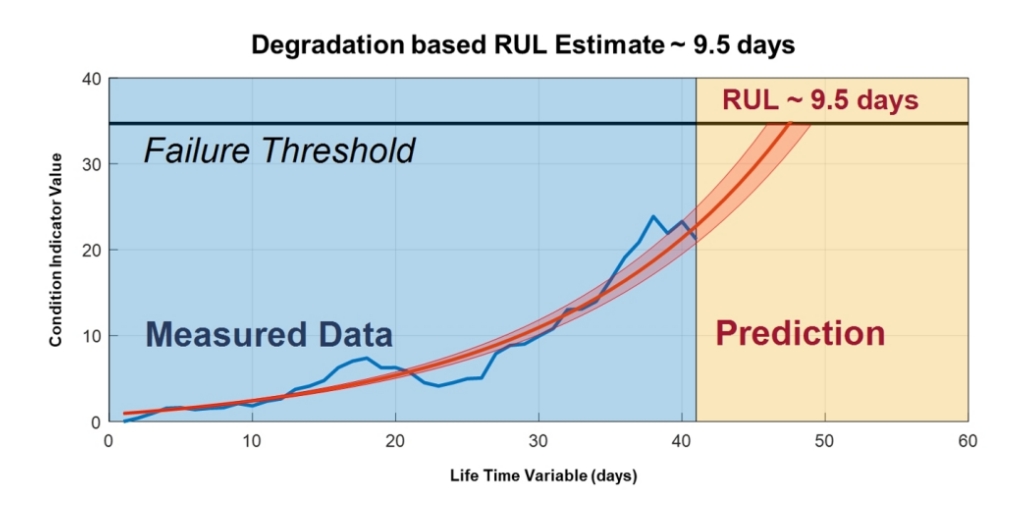

The goal: Predict when maintenance should be performed. Predictive maintenance usually combines various sensor readings, sometimes external data sources, and performs predictive analytics on thousands of logged events. Predicting the remaining useful life of an asset using supervised ML is the most common technique in Predictive maintenance (see Exhibit 2).

- Example 1: Deutsche Bahn, the German railway operator, leverages data from railway switches to predict failures, thus decreasing unexpected delays at scale. Source: Konux Case Study

- Example 2: Nissan runs an AI Predictive maintenance platform to do RUL prognostication on 7,500 assets. The company claims an unplanned downtime reduction of 50% and a payback period of < 3 months. Nissan scaled the solution from 20 critical assets to thousands without increasing the workload of the on-site PdM team. Source: Manufacturing.net

One of the biggest challenges with Predictive Maintenance is the elimination of data imbalances as there is often not enough failure data for all the assets. Data is called imbalanced, when failure events represent less than some specific required share of the dataset. To make accurate predictions on the data, such imbalances have to be eliminated first. There are 2 main methods to achieve balanced data: data sampling and cost-sensitive learning algorithms.

#2: Quality inspection & assurance

Quality inspection and quality assurance is the second largest industrial AI use case category at 20.5%. While there are various ways to do AI-based quality inspection, automated optical inspection is by far the largest sub-category.

Automated optical inspection is a technique where a camera autonomously scans the device under test for catastrophic failure (e.g. missing component) and/or quality defects (e.g. fillet size or shape or component skew). Computer vision is the foundation of optical inspection. Once the images are recognized, semi-supervised ML is the most effective technique to classify images into failure classes. The main benefit of this use case is cost reduction, and the main potential beneficiaries are large manufacturing facilities, where a small reduction in scrap or test time can yield very large savings.

Cost implications: after implementing optical inspection on one of its plants, BOSCH claimed to achieve $1.3M savings due to 45% of total test time reduction. Source: BOSCH.

- Example: A major German automotive company is introducing a deep learning-enabled system for quality control. This system is fully integrated into the flow of the final assembly process and thereby gets rid of the need to have a separate testing area in a controlled environment. The solution is expected to soon replace conventional camera booths that are used today and according to the OEM will result in “immense savings”.

#3: Manufacturing process optimization

Perhaps the most obvious but still one of the most difficult to implement AI use cases is automated manufacturing process optimization. One implementation of this optimization is through Autonomous machines or robots.

The idea behind those autonomous assets is that they replicate monotonous human tasks in the manufacturing process, thus saving costs. Before being put into production, the autonomous machines/robots perform the same task over and over again, learning each time until they achieve sufficient accuracy. The reinforcement learning technique is often used to train robots and autonomous machinery. Under this technique, a robot can relatively quickly teach itself to do a task under the supervision of a human. The “brains” of such a robot/machine are usually neural networks.

- Example: ABB is investing $150M to build an “advanced, automated and flexible” robotics factory in Shanghai. In this plant, ABB will manufacture robots using robots. According to ABB, these robots will have autonomous and collaborative elements. The robots’ autonomy is built with the use of AI and digital twin. Source: ABB.

#4: Supply chain optimization

8% of all industrial AI implementations are improvements to industrial supply chains. Using AI tools to improve inventory management is one of the key applications.

Predictive inventory management leverages predictive analytics for a variety of inventory-related tasks including to reduce inventory planning time, minimize inventory cost, optimize repairments, and find optimal reorder points. For these tasks, techniques such as time-series analysis, probabilistic modeling (Markov and Bayesian models) as well as simulations (e.g., Monte-Carlo simulation) are most commonly used.

- Example: Continental has built software to predict the optimal points for tire changes on its fleet. The underlying model predicts the overall running mileage and compares it to the baseline, to generate actions. By that, Continental is reducing its stock of tires, also improving safety on the road.

#5: AI-driven cybersecurity & privacy

AI-driven cybersecurity & privacy relates to aspects such as cyber threat detection. It typically involves observing the network infrastructure and detecting threats of cyberattacks in real time. It also often includes such activities as network traffic analysis, endpoint detection and response, malware sandboxes, etc. AI-powered cyber threat detection is often part of a larger cybersecurity solution that also uses a number of prevention measures (e.g., firewalls).

#6: Automated physical security

Surveillance & physical threat detection entails real-time surveillance of manufacturing sites or workers in order to automatically detect physical security threats and/or potential safety hazards.

#7: Automated data management

With data often stored in multiple systems and multiple places, it is hard to access and analyze the data quickly and holistically. Therefore, some industrial companies start to employ data management solutions that perform tasks such as data acquisition, data filtering, data cleaning & integration, etc. in real-time.

#8: Smart assistants

Voice assistant is one of the examples of smart assistants in manufacturing settings. Integrating voice assistant technology into its real-time industrial monitoring systems allows workers to gain insights without coding the explicit commands or printing long status reports.

#9: AI-driven research & development

Automated component design is the leading use case in AI-driven R&D. The goal: Letting software independently develop dozens of different designs in short periods, given a set of predefined constraints. The optimal design is chosen afterwards. For this task, digital twins and simulations often complement the AI techniques.

#10: Autonomous resource exploration

Especially relevant in Mining & Quarrying and Oil & Gas industries, autonomous resource exploration is a technique of analysis and processing of the massive volume of images (e.g., radar, satellite or drone images) to detect the optimal point for resource extraction. AI can be especially useful in the detection of captivities in difficult-to-access areas, such as the ocean subsurface or mountains.

More information and further reading

Interested in learning more about the industrial AI market?

The AI use cases discussed in this article are explored in much further depth, including a list of 100+ actual case studies, in the 146-page Industrial AI Market Report 2020-2025.

The report also provides a technology overview, competitive landscape, deep-dive into benefits & challenges, a detailed market assessment, and implementation best-practices and trends.

IoT Analytics’ estimates the global industrial AI market size to reach $72.5B by 2025, up from just over $11B in 2018. The study, published in December 2019, also includes an industrial AI project database (110+ case studies), vendor list (300+ vendors) and market model data (38 tables) in Excel format.

A sample of the report and the database can be downloaded here:

Are you interested in continued IoT coverage and updates?

Subscribe to our newsletter and follow us on LinkedIn and Twitter to stay up-to-date on the latest trends shaping the IoT markets. For complete enterprise IoT coverage with access to all of IoT Analytics’ paid content & reports including dedicated analyst time check out Enterprise subscription.