Hannover Messe (or Hannover Fair) has established itself as the #1 global industrial tradeshow (215,000 visitors and 6,500 exhibitors). The event that took place from April 1-5, 2019 in Hannover, Germany showcased once again the latest developments and industrial IoT trends. The fairgrounds were buzzing and filled with senior executives from most (if not almost all) of the leading industrial hardware, software and service providers. It is one of those rare fairs where you randomly walk into senior executives, like a Head of Engineering for a major industrial conglomerate, and not only into pre-sales people that are giving you the usual pitch.

IoT Analytics had a team of 3 analysts on the ground, visited ~150 booth, conducted ~80 individual interviews and attended ~20 presentations – with the aim to get a handle on the current state of industrial IoT trends and to find out how digital is impacting manufacturing.

Top industrial IoT trends at HMI 2019: 5G, IoT, Cloud

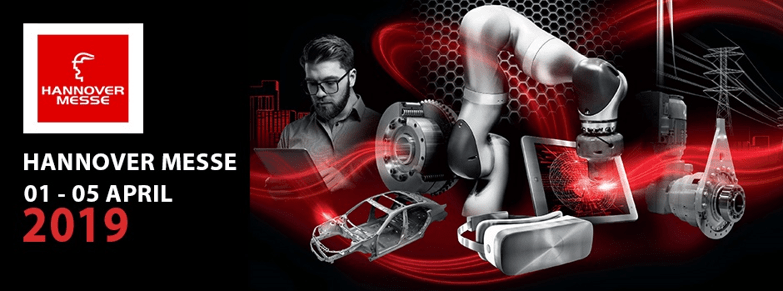

We related our findings to an analysis of articles and press announcements (media analysis) corresponding to different technology topics that were released before or at Hannover Fair. This is the outcome:

5G was the most discussed industrial IoT topic at Hannover Fair 2019 but it didn’t live up to the hype.

The media analysis reveals that 5G was mentioned most often in articles, followed by the terms IoT, Cloud, Platforms and MES. Our examination of the “5G for industry” area showed that there was rather little interest compared to other areas of the fair.

We found that while there is a vision for closed-loop manufacturing using 5G, many experts remain skeptical (for various reasons discussed in our detailed Hannover Messe analysis for IoT Analytics corporate subscribers). Those discussions also showed that “5G for industry” has a number of challenges that still need to be overcome, and in factory settings 5G is likely to only touch smaller, well-defined use cases in the near future (most notably Automated Guided Vehicles AGVs).

IoT was everywhere

Vendors of all types (hardware, software and services) and sizes (start-ups to MNCs) were touting their new “connected” and “IoT” offerings. We counted at least 6 PLC / remote I/O vendors that now offer or will soon offer “IIoT-enabled” hardware: Wago (PFC200), Jumo (variTRON 500), Schneider Electric (Modicon M262), Turck (TBEN-L-PLC), Weidmüller (UC20-WL2000-IOT) and Kunbus (RevPi Connect).

Cloud firms stole the show

Cloud did live up to the hype. The booths of cloud vendors like Microsoft and AWS clearly had the highest amount of traffic at the fair while the stands of other notable software vendors in the same hall were much less in demand. The one cloud company that was absent from the fair was Google.

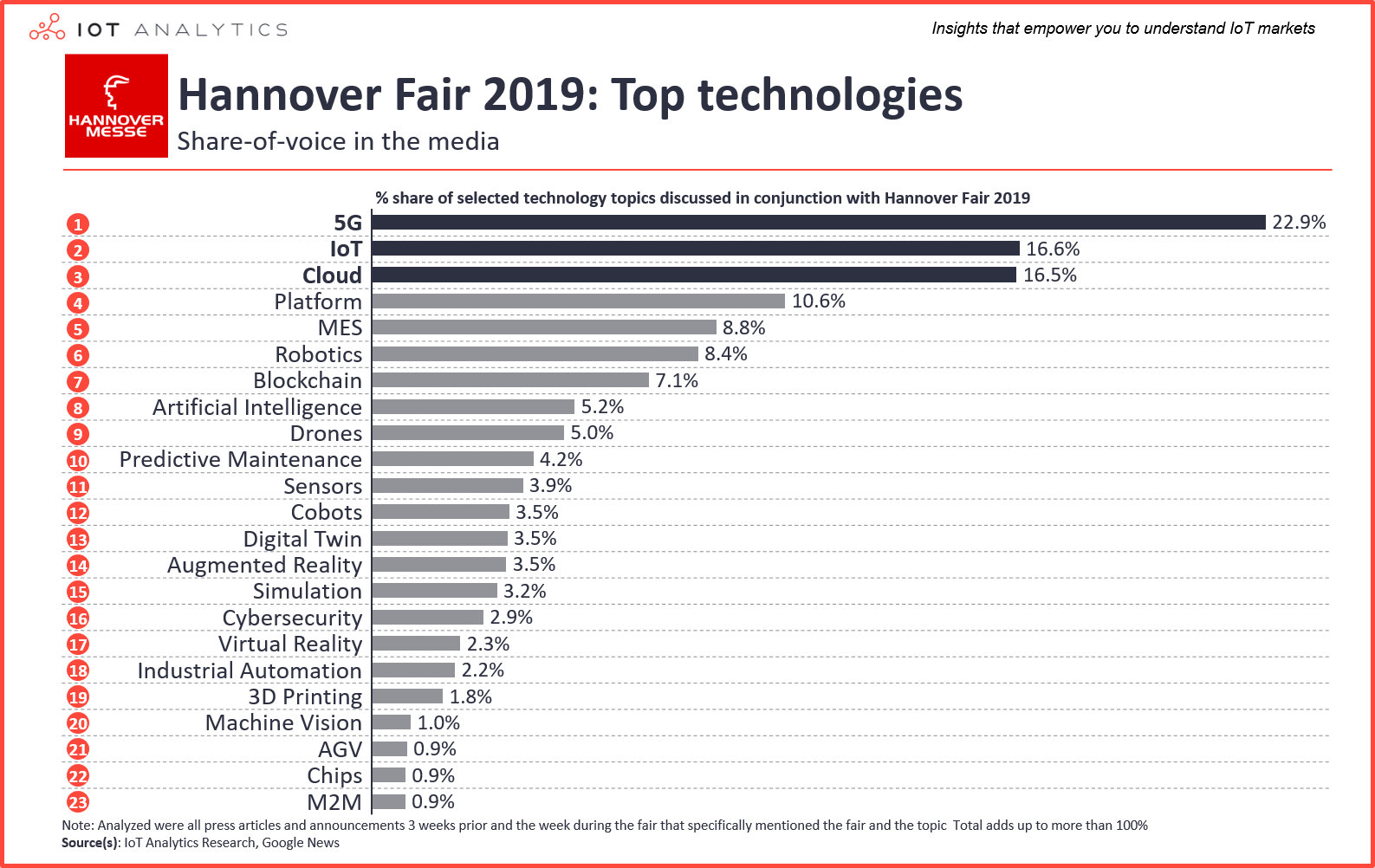

Upcoming industrial IoT trends at HMI 2019: Cobots, Digital Twin, Predictive Maintenance

Compared to Hannover fair 2018, the following industrial IoT trends saw the biggest increase in media coverage: Cobots, digital twin and Predictive Maintenance.

Cobots – robots are becoming mobile and collaborative

Leading collaborative robot vendors (such as ABB, Fanuc, Kuka and others) had large booths promoting how their latest cobots are safer and easier to use. Many of the demonstrations coupled the cobots with other Industry 4.0 support technologies, such as self-driving vehicles (mobile collaborative robots), machine vision (part identification) and additive manufacturing (custom grippers).

Digital twin – physical devices get their virtual counterpart

A number of companies were showing how they have started to develop a digital software replica of some of their assets, often referred to as either “Digital Twin” or “Asset administration shell”. ABB and Festo for example have built digital twins in accordance with the “Plattform Industrie 4.0 asset administration shell (AASX)” standard and were highlighting how this enables a standardized way to quickly connect and analyze data from various assets.

Predictive Maintenance – becoming part of the overall maintenance workflow

The fair showed that a lot of companies are trialing Predictive Maintenance of their assets. In order to keep up with that trend, some of the leading maintenance software providers (CMMS software) discussed how they are now integrating both their own and third-party Predictive Maintenance/Condition Monitoring results into their workflow software. IBM Maximo, for example, has created a suite of tools for engineers to create workflows that act on a probabilistic chance of an asset failing rather than a preventive schedule.

More information and further reading

The analyst team at IoT Analytics has created a 40-page Hannover Messe post-show report which highlights 55 insights from the fair in-depth with pictures and interview quotes. Most of the above-mentioned industrial technologies are discussed in detail. The report also includes a section on 6 of the leading industrial IoT providers (ABB, Bosch, Microsoft, PTC, Schneider Electric, Siemens). The report is available for all IoT Analytics corporate research subscribers.

If you are not a corporate research subscriber you may take a sneak peak by requesting a sample HERE.

This short event recap video from our team also talks about some of the highlights

For continued (free) IoT coverage and updates such as this one, don’t forget to subscribe to our newsletter or follow us on Linkedin or Twitter.