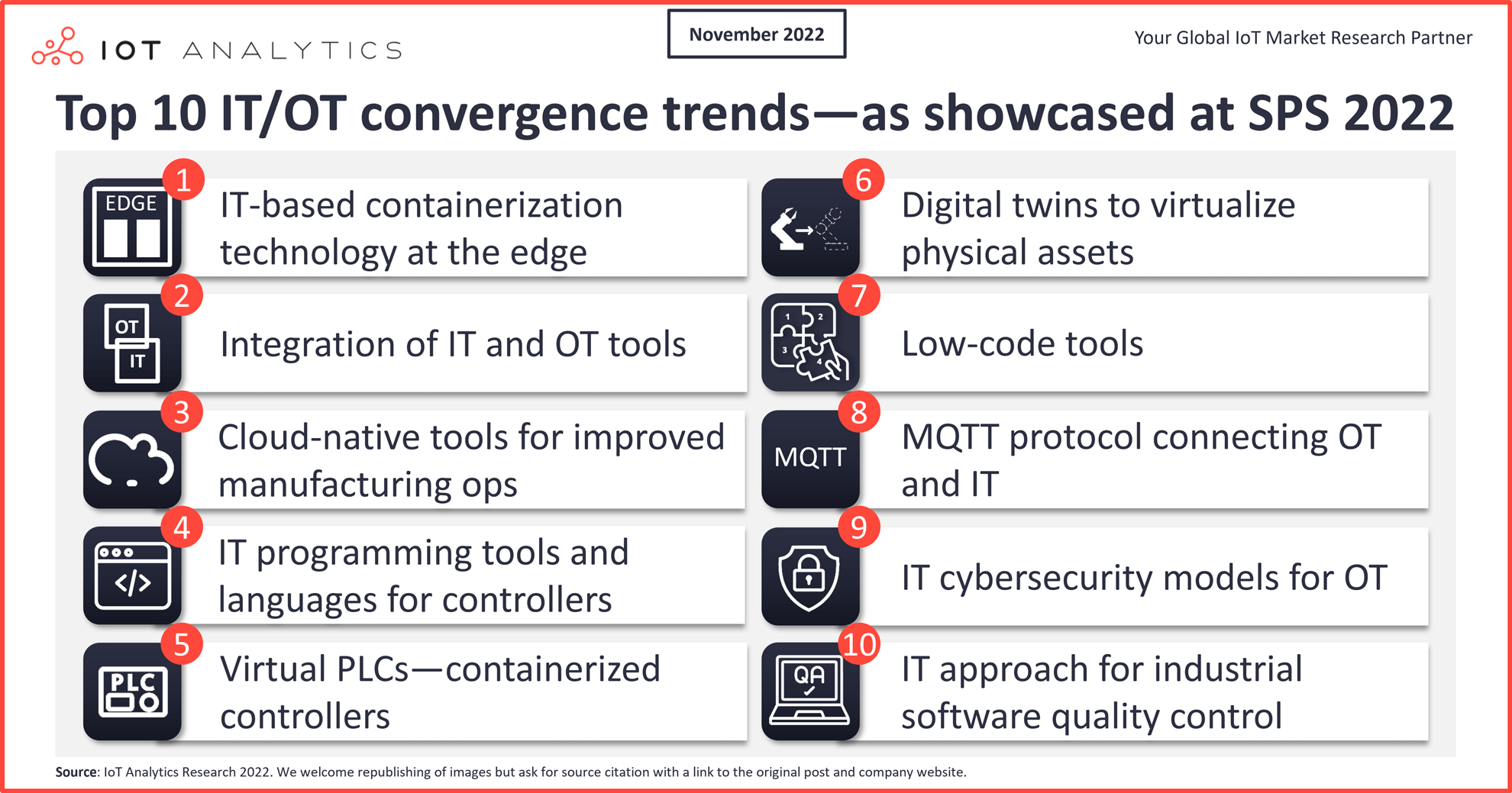

In short

- The current state of IT/OT convergence was on full display at the 2022 SPS—Smart Production Solutions fair.

- Our team picked up 10 trends that show that IT/OT convergence is accelerating.

Why it matters

- SPS is one of the world’s most important industrial automation fairs. Technologies showcased there are widely applicable to any industrial company.

Smart Production Solutions 2022

Smart Production Solutions (or SPS), one of the leading industrial automation fairs, was back in action earlier this month. The event that took place from 8 November –10 November 2022 in Nürnberg, Germany, showcased once again the latest industrial automation developments. Despite a smaller crowd (44,000 visitors—roughly 30% less than pre-pandemic), the fairgrounds were buzzing and filled with senior executives from many leading industrial automation companies, software providers, and related companies. The conference remains a key show for industrial automation hardware and (increasingly) software. It is perhaps the most important fair for some European (especially German) industrial automation companies, such as Siemens, Beckhoff, or Phoenix Contact.

The following quotes highlight the importance of the fair for some of the exhibitors:

“There’s no question, as the leading trade fair for automation, SPS has a regular place in my schedule. Nowhere else do I have the opportunity to meet the large global automation family in one place and take away such important stimuli.”

Christian Wendler, Chairman of the Management Board at Lenze SE

“It feels great to be back at the SPS! We missed this great opportunity here during the last couple of years, and it’s definitely the most important Show for our industrial automation community.”

Fausto Carboni, Chief Executive Officer at the Bonfiglioli Group

IoT Analytics had a team of three analysts on the ground. They visited approximately 75 booths and conducted over 50 individual interviews to get a handle on the latest industrial automation trends with a special focus on IT/OT convergence. This article highlights some of the major takeaways; our research clients can refer to the 51-page “SPS fair 2022—the latest industrial automation trends” event report for an in-depth discussion of individual company exhibitions with examples and important quotes.

Background: IT/OT convergence

The main reason we are seeing interest and movement toward the convergence of IT and OT in the manufacturing space is because of IT technologies’ promise to significantly improve manufacturing. The market dynamics of an increasingly competitive world have “forced” OT, a traditionally less hi-tech sector, to consider these IT technologies. As a first step, IT/OT convergence can happen by creating the necessary (secure) interfaces between IT and OT systems.

However, in recent years, IT/OT convergence is increasingly equated with IT technologies making their way to the OT world. The technologies of the IT world can help elevate the performance of OT assets and processes. IT technologies provide better storage, analysis, and computation. The OT layers stand to benefit from increased productivity, improved decision-making, increased collaboration, better supply-chain integration, efficient energy management, improved customer experience, and new and better business models as a result of utilizing these technologies.

10 IT/OT convergence trends visible at SPS 2022

At SPS 2022, we noticed 10 trends that indicate a serious industry push toward IT/OT convergence. Below is a quick summary of these IT/OT convergence trends. (More details can be found in our 51-page event report.)

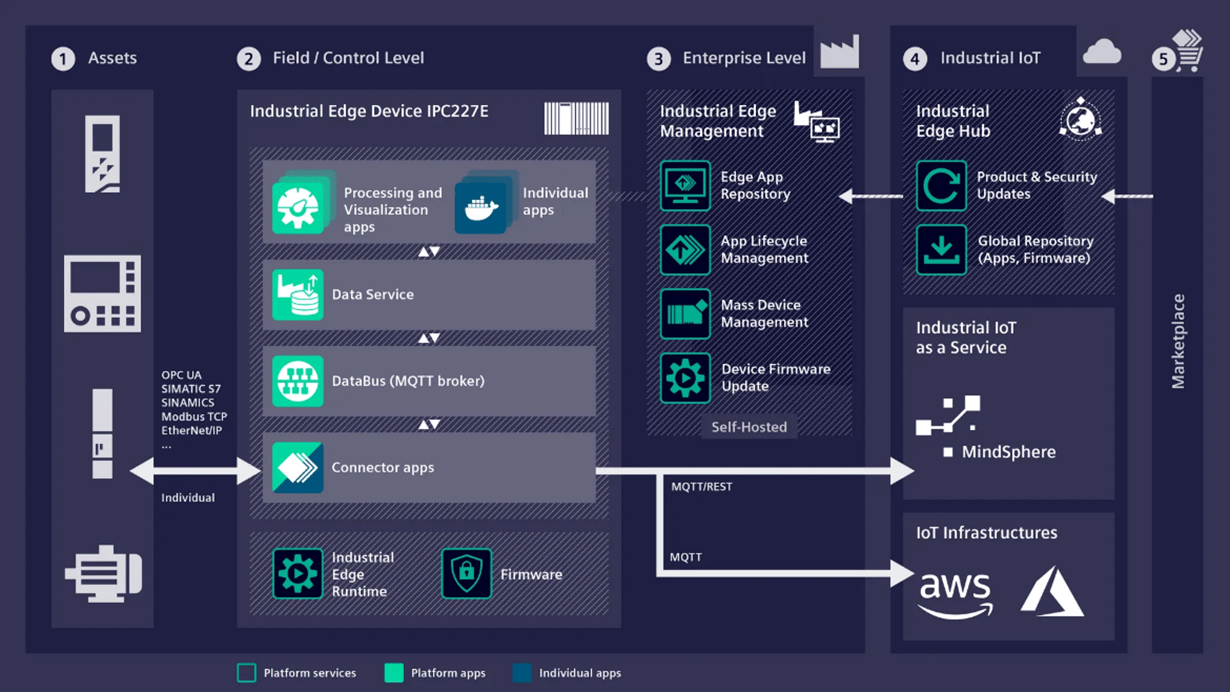

1. IT-based containerization technology at the edge

Vendors such as Siemens, Lenze, Belden, Flecs, MathWorks, Wago, and others highlighted containerized edge workloads. At the fair, Siemens launched its new Industrial Edge Management system (IEM V2.0) based on open-source Kubernetes connected to the cloud. MathWorks showcased a MATLAB Docker Image on a SALZ Automation GmbH PLC/IPC. Wago displayed its PFC200 Series Controllers that can run applications in a Docker environment. Softing highlighted its new edgePlug FANUC CNC application, specifically made to run in a containerized environment on Siemens Industrial Edge to be used for reading machine and manufacturing data from FANUC CNCs.

2. Integration of IT and OT tools

While we have seen OT vendors and solution providers creating converged solutions utilizing IT and OT technologies, one noticeable trend is the close collaboration of IT and OT companies to create integrated solutions. At the fair, Schneider Electric highlighted its new partnership with SAP. The companies plan to enable “easy and seamless integration for joint industrial customers” for their respective OT and IT products. A specific use case highlighted was that of a closed-loop, intelligent asset and field service management using virtual and augmented reality technologies via the EcoStruxure Augmented Operator Advisor.

Software AG displayed how its partnership with thin-edge.io helps achieve a seamless experience from the cloud to resource-constrained edge devices. thin-edge.io is an open-source and cloud-agnostic edge framework designed for resource-constrained IoT edge devices. It runs on a wide variety of hardware, from small, embedded Linux (e.g., Debian and Yocto) devices with low RAM footprint to large, multi-core industrial servers (IPC). It comes with support for multiple programming languages and aims to provide out-of-the-box connectivity, security, and device management features on any device it is deployed on. Note: thin-edge.io is a collaborative project involving contributors like IFM and Software AG and a growing ecosystem of contributing partners, such as Nexus, Inetum, ADAMOS, Brainboxes, Kunbus, and IPComm.

3. Cloud-native (IT) tools for improved manufacturing operations

Siemens shared progress on its open digital business platform for digital transformation called “Siemens Xcelerator”. It is a curated portfolio of IoT-enabled hardware and software, an ecosystem of partners, and a marketplace. Siemens plans to make its entire portfolio of hardware and software modular, cloud-connected, and built on standard application programming interfaces (APIs). Siemens continues to add new (cloud-native SaaS) products to the portfolio and new partners to the ecosystem.

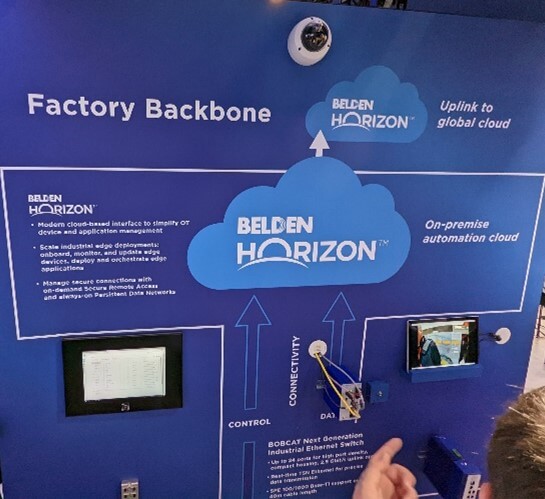

The ecosystem now has 60 partners. Partners at the fair included blue automation GmbH, which showcased the virtual commissioning of a machine using the Siemens executable Digital Twin. Virtual commissioning makes it possible to see whether machines, other industrial equipment, or complete processes will work as planned in the design phase. It simulates the operations and helps identify faulty designs at an early stage, long before anything is commissioned on the plant floor. Belden also showcased its new cloud-based SaaS “Horizon” edge platform. It features SRA (secure remote access), PDN (persistent data network), edge orchestration, data monitoring, and anomaly detection. The edge orchestration component enables users to deploy and manage various edge applications on one or more devices simultaneously, locally, or remotely.

4. IT programming tools and languages for controllers

We see an increase in the availability of IT programming tools for OT programmers. IT programming languages such as Python or Java are also seeing more popularity. Siemens, for example, released a new version (V18) of its TIA portal (software to write control logic), which comes with expanded IT-oriented workflows. Most notably, the Automatic Xpansion (Siemens AX) development environment is now cloud-based, based on Microsoft Visual Studio Code, and allows for version control via GitLab.

Schneider Electric showcased its Automation Expert software which is Schneider’s approach to software-centric PLC programming. The tool is a shared source runtime execution engine based on the IEC 61499 standard, developed by UniversalAutomation.Org. Schneider also demonstrated how the code developed in Automation Expert could be deployed to third-party controllers (e.g., from Phoenix Contact) in a matter of seconds.

5. Virtual PLCs—containerized controllers

In continuation of the recent trends we have seen around soft PLCs, SPS showed us that companies are now moving toward virtual PLCs, which are not only control-hardware agnostic but IT-hardware agnostic (meaning they can run on a commoditized IT server rather than specialized controllers).

Codesys, the pioneer for soft PLCs, launched its new virtual PLC offering—Codesys Virtual Control SL. One of its pilot customers has replaced physical controllers with Codesys Virtual PLCs that run in a containerized environment on an IT server with a VMWare stack. Several start-ups, such as Xentara, Software Defined Automation, and Logiccloud, also showcased their virtual and soft PLCs.

6. Digital twins to virtualize physical assets

While IT/OT convergence is often about OT embracing IT tools, with digital twins, it is the other way around; IT embracing OT in a virtualized environment. The Industrial Digital Twin Association showcased use cases of its asset administration shell (AAS). The AAS is a digital representation of an asset consisting of sub-models that describe the functionalities, parameters, and data of the asset. One such use case was for digital twin energy monitoring, allowing users to switch devices without changing software code. Lenze launched its new open automation platform, Nupano, which allows machine builders to find an overview of their machines as digital twins and corresponding apps.

7. Low-code tools

Low-code development platforms are visual software development environments that reduce the need to write code and time to build and deploy applications. Low-code tools such as Node-Red or Mendix (Siemens) were plentiful at the fair. Siemens showcased how Mendix can be used to develop low-code applications for its Industrial Edge. Start-up 36zero Vision showed its low-code development environment for visual assembly verification (using a Lanner IPC via Bosch Rexroth Ctrl X). Appollo Systems, another start-up, displayed its drag-and-drop low-code tool at the Bosch Rexroth booth. Peakboard highlighted its low-code tool for building production dashboards.

8. MQTT protocol connecting OT and IT

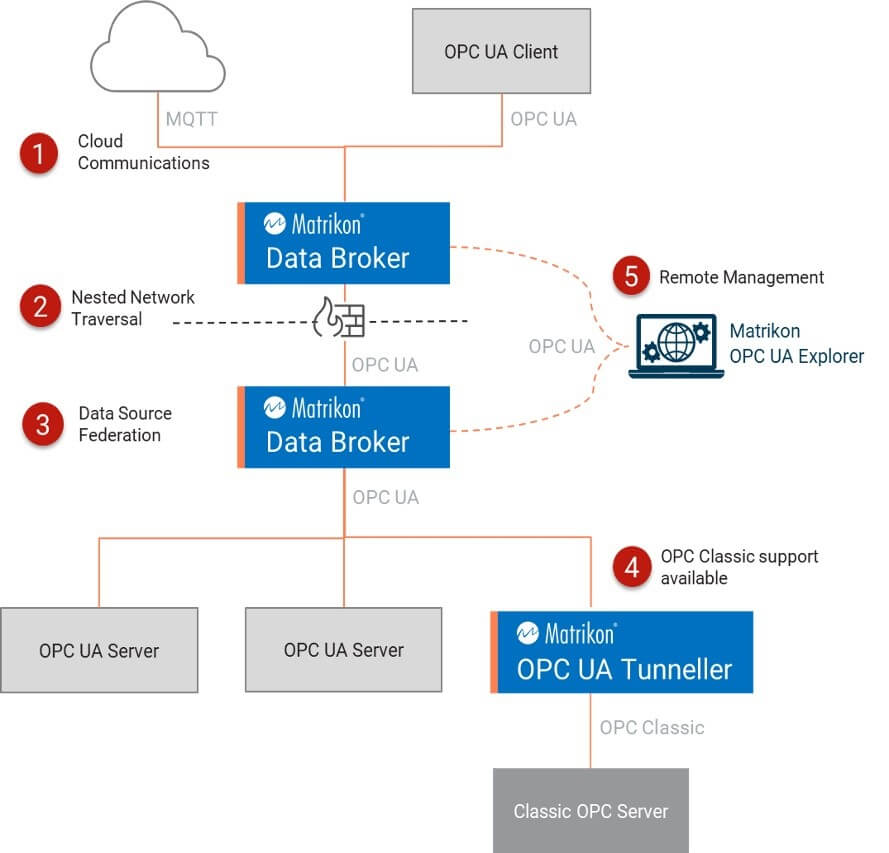

MQTT has been gaining momentum as the protocol of choice for the last-mile connectivity of OT assets to IT/cloud systems. SPS showed MQTT’s importance in conjunction with OPC-UA on the lower levels of the automation pyramid. Matrikon, a leading OPC-UA vendor, highlighted its enhanced “Matrikon Data Broker” that supports sending factory data to the cloud via MQTT. According to a Matrikon representative at their booth, pub/sub-type communication (MQTT being the key protocol here) with the cloud is currently a big customer trend.

HiveMQ, one of the leading independent MQTT brokers at the fair, highlighted the advantages of MQTT. HiveMQ and the Eclipse Foundation have developed the MQTT Sparkplug specification that presents a standardized data format and the ability to discover devices out of the box. With more and more MQTT brokers coming to the market, and some being freely available, HiveMQ highlighted its ability to scale to millions of devices, tools for monitoring data flow and messages, and an advanced bundle of security features.

9. IT cybersecurity models for OT

Cybersecurity company Zscaler showcased how its “zero trust” security principle developed for IT could work in OT environments. Siemens and Zscaler expanded the “Defense-in-Depth” OT concept secured by a Zero Trust Architecture. Based on the principle of “least-privilege access”, Zero Trust only authorizes application-specific access based on verified user identity and context. This is operationalized by installing an app connector for the cloud-based remote access service Zscaler Private Access on a Docker container in the Siemens Scalance LPE local processing engine, thereby creating an access solution for industrial environments.

Microsoft, Moxa, and Swiss Smart Factory showcased how a secure ISA95 security architecture with nested edge and integrated HoloLens can look like—from the cloud to the manufacturing floor.

10. IT approach for industrial software quality control

The PLCopen association, at the fair, announced it wants to form a working group to develop guidelines for a metric-based quality assessment of PLC software. While the announcement could easily go unnoticed, it demonstrates a mindset change in the adoption of proven IT approaches for software quality control in the OT world. Software metrics are a proven means in computer science to objectively assess software quality. This working group aims to develop guidelines on how a metric-based quality assessment of PLC software can be integrated into the daily industrial routine for different stakeholders in machine and plant engineering’s software workflow. (Link)

Where do we go from here?

Industrial automation and software are an approximately $200B billion market today. IT/OT convergence is one of the key technological drivers that will enable new efficiencies and revenue opportunities for manufacturers and drive this market closer to $400B in the next six years. While challenges and concerns remain, SPS 2022 clearly showed that the industry mindset has shifted, and IT/OT convergence is happening.

For example, pre-COVID-19, many OT companies pointed to insurmountable security and privacy hurdles when asked about adopting IT practices and working in the cloud. 2022 is different: As the fair showed, OT companies have started to embrace IT technologies, such as the cloud and containerization, with an extra effort to preserving security and data privacy in this new setup.

On another note: The team would like to give a shoutout to Schneider Electric for being one of the few companies at the fair that embraced sustainability by leading with a carbon-neutral booth completely made from recyclable materials (such as walls made of reusable wooden pallets).

More information and further reading

SPS Fair 2022—the latest industrial automation trends

51-page PDF presenting a comprehensive summary of the key highlights and 20 in-depth insights assembled by the IoT Analytics analyst team at SPS Fair 2022.

Download the sample to learn more about the report structure, companies included, and see additional data points.

Related publications

You may be interested in the following publications:

- SPS Fair 2022—the latest industrial automation trends

- Industry 4.0 Adoption Report 2022

- Industrial Software Landscape 2022-2027

- Virtualization in Industrial Automation Adoption Report 2022

- IoT Communication Protocols Adoption Report 2022

Related articles

You may also be interested in the following recent articles:

- The rise of Industry 4.0 in 5 stats

- The top 10 industrial software companies

- Soft PLCs: Revisiting the industrial innovator’s dilemma

- 5 things to know about IoT protocol

Related market data

You may be interested in the following IoT market data products:

Are you interested in continued IoT coverage and updates?

Subscribe to our newsletter and follow us on LinkedIn and Twitter to stay up-to-date on the latest trends shaping the IoT markets. For complete enterprise IoT coverage with access to all of IoT Analytics’ paid content & reports including dedicated analyst time check out the Enterprise subscription.