In short

- The current state of industrial automation was on full display at SPS Fair 2023—the Smart Production Solutions fair.

- Our five-analysts team produced a 75-page event report and presents its top 10 trends on the state of industrial automation here.

Why it matters?

- SPS is one of the world’s most important industrial automation fairs. The showcased technologies are widely applicable to any industrial company.

Smart Production Solutions 2023

Smart Production Solutions (SPS), a coveted industrial automation exhibition fair encompassing a broad spectrum of digital and smart automation solutions, returned in November, with attendance trending back toward pre-COVID numbers. The event took place from 14 to 16 November 2023 in Nuremberg, Germany. Attendance was up 14% (at just over 50,000) over 2022, though it was still 21% lower than 2019—the last SPS event before the COVID-19 pandemic.

There were 1,229 exhibitors—a 23% climb over 2022—all showcasing their expertise and aiming to help companies understand and meet their challenges today and tomorrow. While traditional tech themes (e.g., control, drive, and sensor technology) were largely present, software and IT took center stage.

“The SPS is still considered the leading automation industry event. The trade fair sets the pace for the market and is the highlight of the year.”

– Steffen Winkler, CSO Automation Business Unit at Bosch Rexroth AG

IoT Analytics had a team of five analysts on the ground. The team visited over 75 booths and conducted over 50 individual interviews to get a handle on the latest industrial automation trends. This article only highlights some of the major takeaways—our research clients can refer to the 75-page SPS Fair 2023—The Latest Industrial Automation Trends report for other takeaways, further examples from those discussed below, key announcements, and insightful quotes from key industry automation players.

Click here to read our coverage of SPS 2022, focusing on IT/OT convergence.

The insights in this article are based on the recently published 75-page

SPS Fair 2023 – The Latest Industrial Automation Trends

Download a sample to learn more about the report structure, new announcements, additional data points, trends, and more.

Already a subscriber?

Browse your reports here →

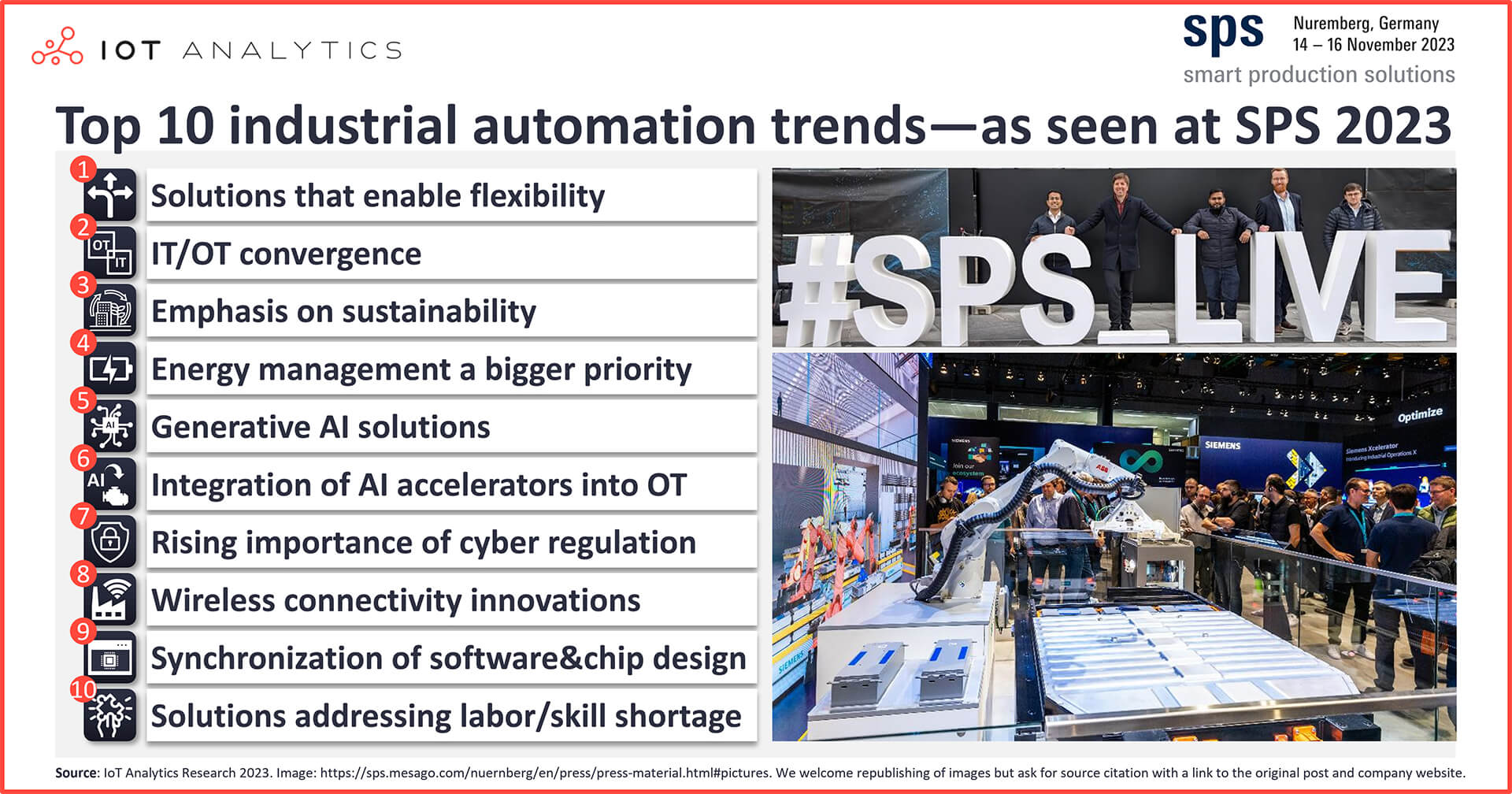

10 industrial automation trends observed at SPS 2023

At SPS 2023, we observed 10 trends indicating an expansion in industrial automation solutions. Here are brief summaries of each from our SPS 2023 report.

1. Solutions that enable flexibility

Over the last three years, manufacturers have battled unforeseen demand shifts, drastic supply constraints, and a variety of workforce challenges. Several exhibitors at SPS 2023 highlighted the increasing necessity for flexibility in manufacturing to adapt to dynamic market conditions. For example, German technology conglomerate Siemens showcased its digital twin, emphasizing flexibility by enabling engineers to quickly change machine configuration details during design and validation.

Similarly, German engineering firm Bosch Rexroth’s DeviceBridge exemplified seamless connectivity solutions, while French software company Dassault Systèmes’ 3DEXPERIENCE demonstrated the modularization of software—all contributing to more adaptable and resilient manufacturing processes.

2. IT/OT convergence

In our coverage of SPS 2022, we focused on IT/OT convergence trends. This convergence comes in many forms, and this year, we saw many of those forms on display at exhibits. Two forms that particularly stood out were industrial data ops and hardware-independent control systems.

US-based industrial automation vendor Rockwell Automation exemplified industrial data ops with DataMosaix, which it released a week before SPS as part of its FactoryTalk Hub. The solution integrates data from various sources, including gateways, historians, MES/MOM, PLM, and enterprise systems. Additionally, US-based industrial software company HighByte demonstrated its latest Intelligence Hub (V3.2, released in late September) at the AWS booth. This version supports Unified Namespace (UNS) and expands data pipeline capabilities like sequencing transactions with MES and ERP systems.

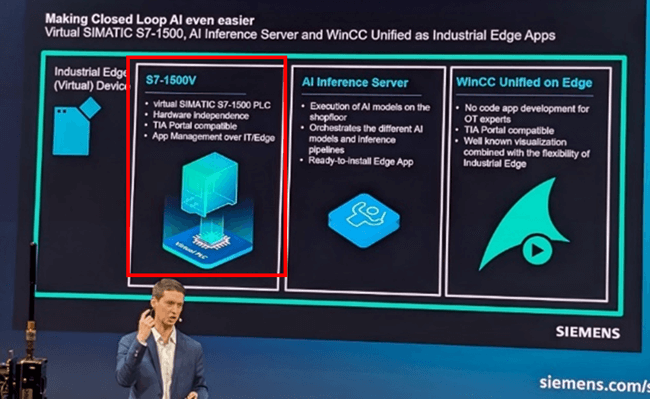

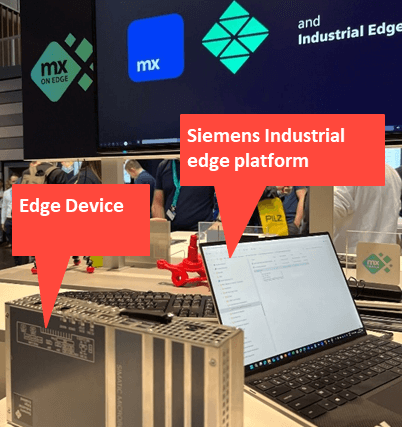

Regarding hardware-independent control systems, several OEMs highlighted their advances in developing and enhancing their hardware-decoupled PLC runtimes—either vPLC or soft PLC. For vPLCs, Siemens demonstrated their SIMATIC S7-1500V, a virtual version of its physical SIMATIC S7-1500 PLC that mirrors functionality but is independent of hardware. Meanwhile, Codesys discussed its upcoming containerized vPLC solution, Virtual Control SL. Codesys plans to release this solution very soon.

For soft PLCs, Phoenix Contact, a Germany-based industrial automation company, showcased its PLCnext Control solution. This solution utilizes a Linux kernel with the PREEMPT_RT patch and YOCTO toolkit to create a real-time runtime system on its hardware. However, Phoenix Contact plans to release a Docker image of the runtime that can be used independently of its hardware, turning this solution into a vPLC.

These were only two aspects of the many that we witnessed at the fair, and research clients can read more about the others in the full report.

3. Increasing emphasis on environmental sustainability

A significant shift towards sustainability was evident. With sustainability and energy transition remaining key topics in company boardrooms in 2023, we were not surprised to see a notably larger emphasis on sustainability at SPS 2023.

France-based automation vendor Schneider Electric placed sustainability in the spotlight at its booth—for example, it showcased a use case for machine vision and AI in recycling chips from electrical devices. Meanwhile, Catena-X’s board members explained that there is a growing demand for visibility on carbon emissions across the supply chain and discussed its open data ecosystem designed to meet that demand.

4. Energy management becoming a bigger priority

Beyond just sustainability, industrial automation vendors also shared energy management solutions at their booths. These solutions aim to help manufacturers meet the EU’s 2030 sustainability goals and regulations and those of other regions and countries they operate within. The EU’s Renewable Energy Directive (EU/2023/2413) requires member states to meet a 55% reduction in greenhouse emissions and a minimum of 42.5% share of renewable energy sources by 2030. To achieve these goals, the EU has imposed stricter environmental regulations on manufacturers, requiring them to adopt energy-efficient solutions or face penalties.

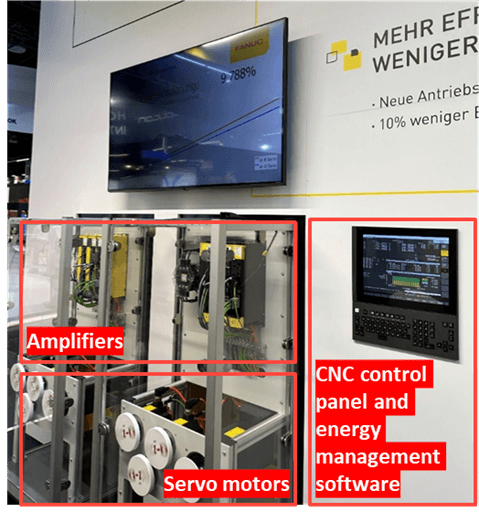

Japan-based automation equipment manufacturer FANUC showcased its new αi-D (“alpha i”) series SERVO motor system, offering high-speed and high-precision performance with less energy consumption. Additionally, Michael Koch, a Germany-based energy management systems provider, demonstrated its line of active energy management devices—Pxt. These devices are designed to manage breaking energy, bridge power failures, compensate voltage dips, reduce mains load peaks, increase energy efficiency, and enable controlled stops on power failure.

5. Generative AI solutions in industrial applications popping up

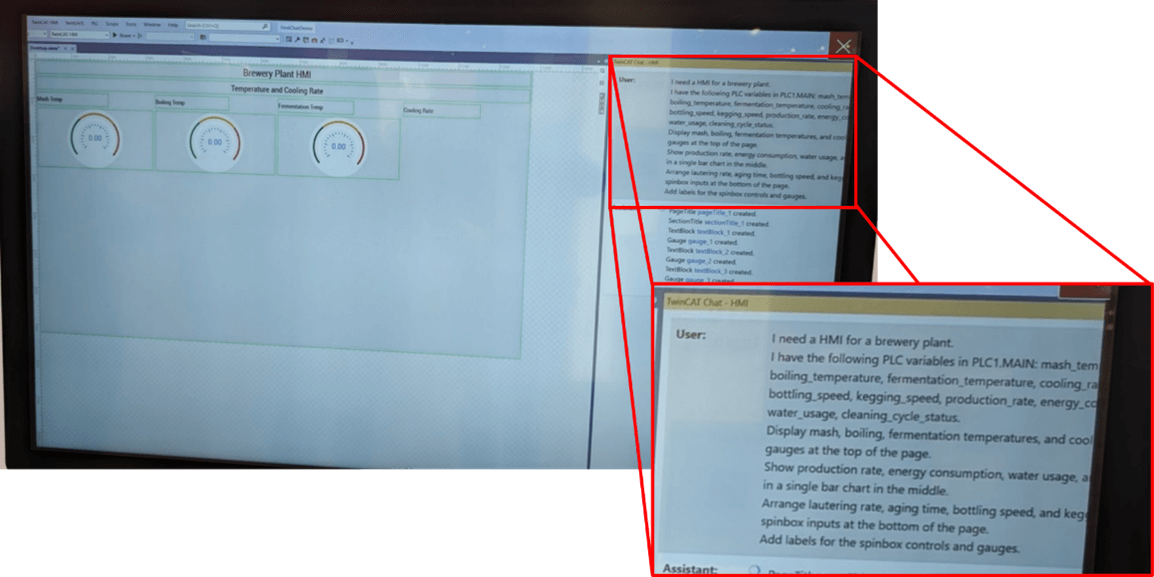

Generative AI emerged as the key 2023 trend. While the 2022 SPS fair did not have a generative AI showcase, our team identified 14 different AI showcases this year, though there were likely more.

Germany-based Beckhoff‘s TwinCAT Chat demonstrated AI’s role in coding, Bosch Rexroth‘s AIRO assistant in support/troubleshooting, and Siemens‘ Industrial Copilot in operational analytics—among other things. Unsurprisingly, Microsoft and OpenAI are behind most of these solutions. However, major cloud provider AWS—with its Amazon Bedrock offering—also presented its technology at the fair, highlighting the growing field of generative AI providers and integration into industrial settings.

Keep an eye on our research blog and reports pages for our upcoming Generative AI Market Report 2023–2030, expected to be released in mid-December 2023.

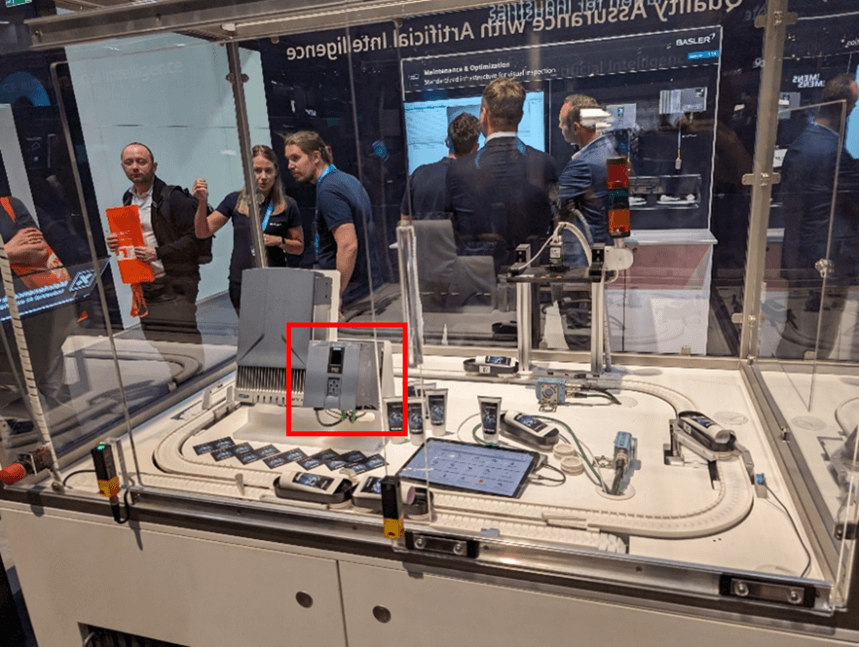

6. Integration of AI accelerators into industrial hardware

We found that AI accelerators are increasingly being built into industrial hardware, enabling AI-driven operations like machine vision or process optimization. In collaboration with machine vision software provider MVTec and machine vision hardware supplier Basler, Siemens showcased AI-accelerator use for machine vision applications. Additionally, French energy management and automation company Schneider Electric presented its integration of Hailo’s AI accelerators in some of its solutions, and Beckhoff shared its new IPC C6043, which leverages an NVIDIA RTX A4500 GPU. These represented further advancements in embedding AI capabilities directly into industrial equipment.

7. Rising importance of cybersecurity regulation and certification

Generally, there appeared to be a growing alignment with the IEC 62443 cybersecurity standard and more commitment to OT cybersecurity than in past fairs. Recent geopolitical events have raised the need for transparency in cybersecurity, and the upcoming widespread EU adoption of the NIS2 Directive has companies looking for proactive measures to meet the regulation. At the fair, Japan-based robotics vendor Yaskawa announced it had received 62443-4-1 certification, and Phoenix Contact showcased its IEC-62443-4-1–certified mGuard routers—both of which serve to demonstrate this trend toward heightened cybersecurity measures.

8. Wireless connectivity innovations in industrial spaces

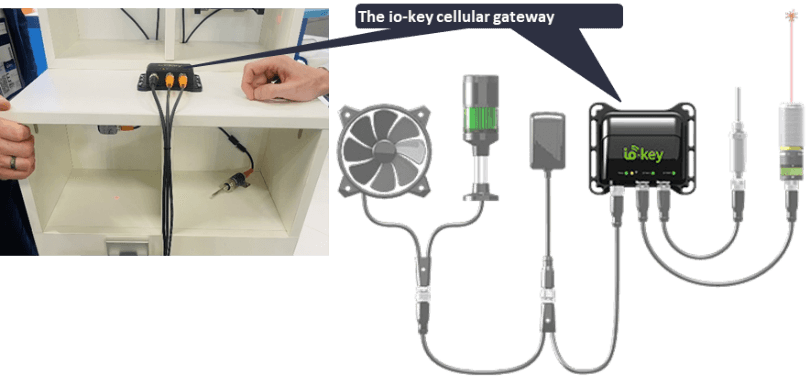

OEMs had new wireless connectivity innovations geared toward industrial spaces on display this year, particularly new industrial 5G products. Phoenix Contact unveiled the TC ROUTER 5004T-5G EU for industrial 5G applications, and Siemens showcased its Private Industrial 5G infrastructure, which is suited for challenging industrial settings. Underscoring the growing role of wireless technologies in industrial environments, sensor and automation technology provider Autosen introduced its io-key wireless IoT gateway for remote sensor data monitoring, and Phoenix Contact demonstrated its NearFi technology, which enables contactless transmission of power and data.

9. Synchronization of software and chip designs for enhanced performance

Our team noted the synchronization of software and chip designs as an emerging trend. Indeed, the industrial automation ecosystem appears to be coming together to enhance hardware and software performance, with software companies optimizing specifically for specific chip architectures and different vendors.

Beckhoff unveiled its TwinCAT MC3, which allows for parallelization of motion control on different chip cores. Siemens shared how it collaborated with virtualization tech company VMWare and semiconductor chip manufacturer Intel to reduce latency in virtual PLC setups, highlighting a strategic alignment between hardware and software capabilities in industrial technology.

10. Solutions addressing labor and skill shortages

Several senior executives highlighted the industrial sector’s response to the significant labor and skill shortages. German software startup Wandelbots pitched its robot programming software around the labor shortage, while Siemens’ showcasing of the aforementioned Mendix software addressed making software development more accessible and easing skill shortages—programming, in this case—in manufacturing.

Where do we go from here?

In 2022, IoT Analytics estimated the broader overall industrial automation market—including industrial software and OT—to be $247.7 billion (our updated Industrial Software Landscape report is scheduled for release in Q1 2024). The industry is very dynamic, and trends and solutions such as the ones highlighted above are helping propel the market forward, possibly toward $422 billion by 2027.

This year’s theme of “Automation meets IT” could be the theme for years to come, as only the combination of both (also often referred to as IT/OT convergence) will help address many of the industry’s challenges. In general, we observed that exhibitors highlighted common challenges that their customers face, e.g., labor shortages and cybersecurity. We also observed an increased awareness of sustainability targets and energy footprints. The new generative AI wave is the latest excitement in the industry that may be able to help in support or coding use cases.

Our prediction for SPS 2024 is that we will see both the first virtual PLCs and the first industry-geared generative AI solutions that can be purchased from a store. Along with these, we hope to see further advancements toward sustainability and cybersecurity.

More information and further reading

Are you interested in learning more about the industrial IoT market?

SPS Fair 2023 – The Latest Industrial Automation Trends

A 75-page PDF presenting a comprehensive summary of the key highlights and 17 in-depth insights assembled by the IoT Analytics analyst team at SPS Fair 2023.

Already a subscriber?

Browse your reports here →

Related publications

You may also be interested in the following reports:

- Predictive Maintenance & Asset Performance Market Report 2023–2028

- Industrial IoT & Industry 4.0 Case Study Report 2023

- Global Cloud Projects Report and Database 2023

- IoT Gateway Market Report 2023–2027

- 5G Market Report 2019-2025

- Digital Twin Market Report 2023-2027

- Machine Vision Market Report 2022-2027

Related articles

You may also be interested in the following articles:

- Predictive maintenance market: 5 highlights for 2024 and beyond

- Industry 4.0 check-in: 5 learnings from ongoing digital transformation initiatives

- Digital twin market: Analyzing growth and emerging trends

- The vital role of industrial IoT gateways in bridging IT and OT

- Mapping 7,000 global cloud projects: AWS vs. Microsoft vs. Google vs. Oracle vs. Alibaba

- The Leading 5G IoT Use Cases

- Top 7 upcoming machine vision applications—enabled by recent advances in AI, cameras, and chips

Related dashboard and trackers

You may also be interested in the following dashboards and trackers:

- Global Cellular IoT Connectivity Tracker & Forecast

- Global Cellular IoT Module and Chipset Market Tracker & Forecast

- Global IoT eSIM Modules and iSIM Chipsets Market Tracker

- Global IoT Enterprise Spending Dashboard

Subscribe to our newsletter and follow us on LinkedIn and Twitter to stay up-to-date on the latest trends shaping the IoT markets. For complete enterprise IoT coverage with access to all of IoT Analytics’ paid content & reports, including dedicated analyst time, check out the Enterprise subscription.