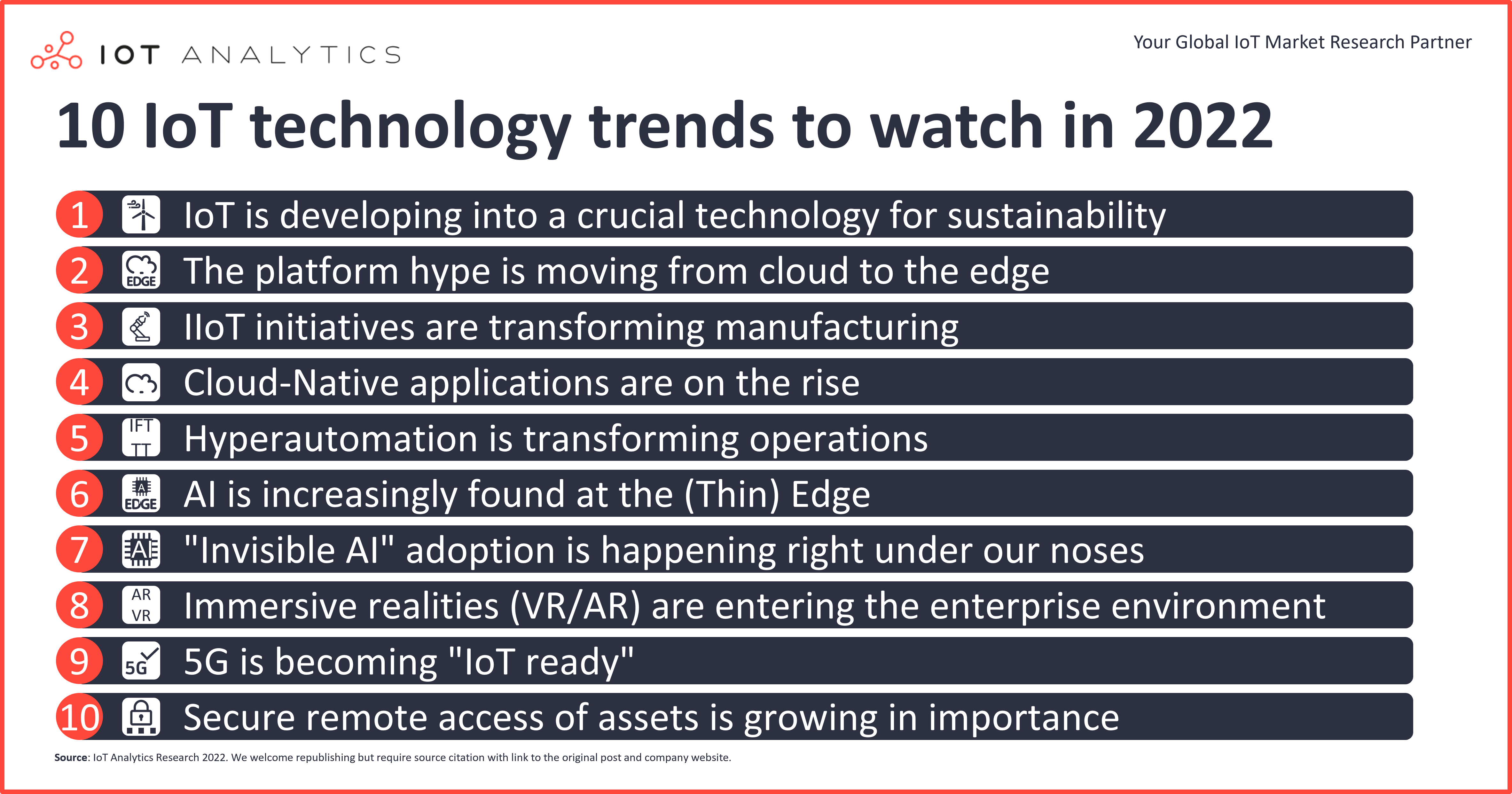

At IoT Analytics, our market analyses rely on the findings from our analyst team but also on the input from experts and advisors. We gathered our advisor’s opinions on the most important IoT technology trends to watch in 2022:

Note: You may also be interested to read our recent article on more general IoT adoption trends

In short

- Our advisors identified 10 major trends shaping the IoT technology world of 2022

- Industrial trends include a continuous digitization/automation of the production process, including “Invisible AI” adoption, which is increasingly found at the Edge.

- In the IoT Platforms & Software related field, the cloud is getting more robust, with cloud-native applications on the rise, and the platform-hype moving to the edge

- Securing all IoT devices and data will long be a major concern

Why it matters

- For vendors and end users alike it is important to understand how they can capitalize on the latest IoT technology trends and leverage the latest IoT advancements.

1. IoT is developing into a crucial technology for sustainability

Within the IoT community, the capability of intelligent connected devices to enable and advance applications such as environmental monitoring, territorial management, and energy optimization is well-known. However, the business value of those applications has been limited and heretofore sidelined by most major IoT players. With the rising focus on building a green economy and mitigating climate change, IoT technology has the potential to enable green solutions for enterprises, cities, and communities. These applications, including reducing energy costs, enabling remote deployments, monitoring failure points, and many others, will soon go from marginal cases to drivers of IoT expansion. A key objective of the IoT community should be to stress the integration of IoT into any viable model of a sustainable global economy.

Examples

There are many examples of environmental monitoring via IoT, such as Libelium, and IoT-based territorial management (for example Dryad Networks or Kerlink and NetOp for fire management, or Opti for floods management). From a policy perspective – and here policy is important because we are talking about public money primarily – this idea of Industry 5.0 introduced by the European Commission, in which the 1.0 more than the existing 4.0 is not about new technology, but about the role of advanced technology for sustainability in industry. Add to this the investment of EU Next Gen Europe of almost €800 bn with a large focus on green (approx. 30%) and digital (approx. 30%).

Advisor quote

“Through the data gathered, the IoT maps the environmental conditions of spaces and territories. The IoT becomes then the observatory of our fight against climate change. Let us use it wisely and let us listen to it!”

2. The platform hype is moving from cloud to the edge

As previous IoT Analytics research has illustrated, clear leaders have emerged in the frantic IoT platforms race that began in earnest in 2015. Edge platforms, specifically those in the industrial space, are in their infancy, and 2022 will mark the year when competitors in the race try to separate from the pack.

Virtualization technologies such as VMs and containers enable application portability across compute hardware vendors. These technologies are widely adopted by IT departments, but many OT departments still procure applications by purchasing boxes that run that application (e.g., they purchase a protocol convertor to translate one Ethernet protocol to another, or a PLC to run some control logic workload).

At the risk of grossly over-simplifying the market landscape, the edge platform vendors can be grouped based on the types of hardware, clouds / IoT platforms, and edge applications they support. The vendors can also be grouped based on what their core business is: hardware vendors (including OT hardware vendors such Siemens, Phoenix Contact, and Bosch and IT hardware, such as Cisco, HPE, etc.), cloud vendors (e.g., AWS, Azure), and software vendors (e.g., Zededa, CPLANE, etc.).

As in most technology land grabs, customers will ultimately decide who wins this race. Will cloud providers dominate this space, or is there room for the hardware vendors and software start-ups? If there is room for non-cloud players, will customers prefer a platform that is hardware-agnostic and provides a single pane of glass for managing all of the workloads across all types of devices, or will they prefer to have a hardware-specific platform (i.e., the edge workloads can only run on hardware supplied by the edge platform vendor) that provides tighter integration between the hardware and the management platform as well as a single point-of-contact in case problems arise?

If the latter is true, we may see an IoT technology trend toward more vendor lock-in on edge platforms that only work with hardware from a specific vendor. If the former is true, the hardware-agnostic software companies building these edge platforms will still need cooperation from the hardware vendors on which the edge applications will run.

Example

As part of a series of initiatives in late 2021 targeting edge applications, Dell announced a partnership with Litmus, a flexible and scalable IoT platform, to help enterprises operate at the whole of the IIoT edge (including devices, applications and data) with a resilient and secure connection “from the factory floor to the enterprise cloud”.

Advisor quote

“In any outcome, cloud providers certainly won’t come last in the race, as many companies will standardize on their edge platforms, and most companies will eventually send at least some data from the edge to a cloud provider, regardless of which edge platform they use.”

3. IIoT initiatives are transforming manufacturing

Engineers tend to look at technology as a solution while often overlooking what the root of the problem may be. The role of IoT is to go beyond SCADA (Supervisory Control and Data Acquisition) for machine operations by supplying data needed for timely decisions about maintaining assets. In the recent past, an IoT project was simply a digitizing process. Now that more data is accessible, manufacturing professionals need to ask the question, “What specific business problem are we solving?”

Example

Many marketers discuss predictive maintenance as the “killer app” for IoT. At the 2021 International Maintenance Conference, the discussion among attendees and presenters was not some vague predictive maintenance strategy. Rather, they are using data generated from IIoT projects within predictive analytics applications. Problems projected by the analytics often automatically feed a workflow engine leading to maintenance and reliability activity that avoids unplanned downtime thus optimizing production. So for example, when BASF added predictive maintenance to one of its plants, via Schneider Electric, it focussed first on monitoring the power substation that supplied the plant, as well as the health of the motors and their control centers consuming that power. Having a specific business problem, i.e., maintaining uninterrupted power to a busy plant, provided a narrow and achievable scope to a predictive maintenance solution.

Advisor quote

“IoT projects have provided data now used to predict machine problems and automatically guide technicians to solutions leading to optimized production.”

4. Cloud-Native applications are on the rise

Companies are now making cloud adoption and migration a top priority for the near term, at least through the next several years. Those that are already heavily invested in the cloud are seeking new ways of driving efficiency and increasing capabilities, while the rest will need to rapidly develop migration plans. For a decade now, the cloud market has grown at a steady rate, but the pandemic has significantly accelerated this growth, in terms of both overall adoption and number of use cases. As cloud becomes the norm for many at the infrastructure, platform, or software level, the industry will see a whole new wave of applications developed and optimized for cloud scale and performance, which in turn will help deliver increased reliability and decrease time to market, meaning software applications can be deployed faster and with more flexibly while at the same time reducing infrastructure complexities and costs.

Example

After the first wave of the Covid-19 pandemic dramatically and immediately shifted working patterns, Communications Service Providers (CSPs) including global telecoms operators, broadband internet providers, and satellite broadcast service providers, were forced to rapidly upgrade their cloud services to cope with an unprecedented increase in demand, including from comparatively novel use-cases, such as social video meet-ups. They had to make these massive, structural upgrades while also sending all but the most essential staff from home, meaning improvements in infrastructure needed to reduce maintenance and oversight. This in turn was a huge driver in the expansion of Cloud-Native Applications, which by their nature do more with less. A survey by TM Forum reported that 38% of CSPs were at the mid-way point of implementing their digital transformation strategies in 2021, a 50% increase year-on-year, with 45% of those strategies involving the introduction of Cloud-Native applications. Late last year, Vodafone, for example, launched a partnership with Vmware to provide a single common platform for all of Vodafone’s operations in Europe, starting with 5G Standalone.

Advisor quote

“Two of the major drivers I see in the development of cloud-native application are serverless computing and containerization/Kubernetes, primarily because both will increase the speed at which cloud-native applications can be deployed—faster deployment, coupled with higher reliability, will make adoption a case of when, not if, for a huge range of use-cases.”

5. Hyperautomation is transforming operations

Current conventional wisdom is that AI is the key to transforming any enterprise application, but the reality is that currently, most AI requires serious “data ditch digging” to get to the point of benefiting an enterprise. AI is only part of the transformational equation, and the second (and frequently missing) missing part is Robotic Process Automation or RPA. And when AI and RPA are correctly combined and applied, the result is hyperautomation.

The pandemic created an inflection point, prioritizing workers’ safety and the technologies needed to support them, and the labor shortage which began before the pandemic has become even more challenging of a constraint to deal with, which is accelerating the use of hyperautomation to improve process performance from the shop floor to the top floor.

Example

In Brazil, Deloitte used IBM’s AI-augmented RPA solution to transform their monthly reporting cycles, automating the generation and error-checking of reports garnered from dozens of sources, with a direct link to Central Bank figures so currency exchange figures were constantly updated. The total time spent on report generation went from almost two working weeks to just a single hour per month, while monthly the same Smart RPA reduced monthly travel expense report preparations from three hours to ten minutes.

Advisor quote

“Two years ago I wrote about the “attack of the bots” in manufacturing focusing on how Robotic Process Automation can eliminate a massive number of repetitive tasks and consequently increase productivity and help eliminate errors. Now you can layer AI into the equation and use it to make those decisions for RPA. It is the ultimate extension of IFTTT.”

6. AI is increasingly found at the (Thin) Edge

Organizations have been rethinking where to place their AI workloads, in the cloud or at the edge. Up to now, AI edge applications have run on compute- and power-intensive edge devices e.g. industrial computers and edge routers. However, two developments are driving a shift to the thin edge.

- Developments in semiconductors especially at the lower-cost, lower-power end of the spectrum, mean that AI can be put ever closer to the smallest level of device. There is every reason to believe a large number of microcontrollers (MCUs) will have on-device AI within the near term.

- AI algorithms have become more efficient in the last 5 years. For example, current AI algorithms need far less compute power than just a few years ago to train a neural network for visual object recognition. Some experts have postulated a 2x reduction in compute power needed every 16 months.

Example

In 2021, MCU giant Renesas introduced a new entry to its hugely popular RZ/V lineup, featuring a GPU for thin-edge image processing, offering real-time AI-based color correction and noise reduction for machine vision applications, all from an entry-level product.

Advisor quote

“What we will see increasingly is AI applications shift to the Thin Edge – devices that run on MCUs with very little memory, computational power, and low power consumption.”

7. “Invisible AI” adoption is happening right under our noses

The goal of replicating human cognition has been discussed and sought after for thousands of years. Artificial Intelligence is not a product. You can argue it isn’t even a technology. In itself, it isn’t an invention either. There is no single day we can mark as its inception and we most likely won’t know when it ends. Yet it is already essentially ubiquitous! Driven by advancements in other technologies, such as computing power, cost of computing resources, the internet, sensors, and most of all the development of complex machine learning algorithms and models. More than anything, AI is a quest; a journey striving toward the goal of creating an intelligence, and as such it is constantly improving, expanding, and changing. What makes AI different from most other Industry 4.0 technologies is its ability to harness creativity and imagination. The sky is the limit on what it can do.

AI is extremely versatile in its application – it spans every industry and impacts nearly every job function – from entry-level up to CEO. It has a mysterious, science-fiction allure that captivates people’s curiosity and imagination. Yet, because many people struggle to understand exactly how it works, a portion of the population is afraid of using AI to help with decision-making and a vast majority are hesitant to let AI implement decisions on their behalf.

Example

In 2021, American pharmaceutical company Charles River Laboratories announced a partnership with AI-based drug design group Valence Discovery. The partnership’s goal is to leverage Valence’s REACTOR technology, which is capable of modelling the series of individual chemical reactions that occur once a drug is taken through advanced AI. Doctors prescribing the drugs and patients taking the drugs would never know the drug was developed using AI.

Advisor quote

“Because AI is so ubiquitous it is starting to infiltrate our lives in more ways than we realize, oftentimes right under our noses. When most people interact with or plan to use AI they do so with a very deliberate purpose to solve a specific problem. I like to refer to this as ‘Intentional AI’. However, with so many companies now including AI within their products, platforms, and services, AI is used to help us whether we realize it or not. This is known as ‘Invisible AI’, and if fully appreciated can help solve trust barriers with those hesitant to use AI. Instead of experiencing one big use case with AI, we will all have 100s of interactions on a regular basis”

8. Immersive realities (VR/AR) are entering the enterprise environment

While humans are already living and working in smart environments, finding more efficient and effective ways of coexisting in these spaces has become an important focus for researchers and companies. That means increasing operational efficiency and quality in working environments, but also developing remote operation management. The Covid-19 pandemic has reinforced the attention on the latter. For this, the convergence of IoT with immersive reality technologies and environment simulation technologies (such as Digital Twins) is necessary. Considering such a convergence will require a lot of data, the rise of 5G – and consequently of edge computing – will accelerate the development of VR and AR applications for enterprise and industrial applications.

Examples

Lufthansa Technik’s collaborations with both Vodafone and Nokia bring together an IoT environment with 5G, AR, and Digital Twins. The aviation giant’s service arm deployed two separate private 5G networks in two separate maintenance campuses. AR overlays augmenting the video stream allow customers to have issues observed and diagnosed remotely, while also allowing the group to consult worldwide with partners using AR and Digital Twins.

Advisor quote

“The era of smart relationships between humans and machines is coming, due to the convergence of the IoT and technologies such AR and VR. All that for the sake of efficiency and new and safe forms of remote and infield work”

9. 5G is becoming “IoT ready”

Consumer-oriented pundits thought of 5G as simply a mechanism for faster downloads. The real power for industrial and commercial purposes lies in private networks built on 5G. By the end of 2022, 5G will be considered just another tool. Engineers use it not thinking about being pioneers but just about solving a problem. Once they start, it will be just another engineering job that improves production and quality.

Example

Nokia has deployed a private 5G standalone wireless network for Volkswagen at the car maker’s main plant in Wolfsburg, Germany. The private campus network uses the Nokia Digital Automation Cloud (DAC) solution to provide reliable, secure, real-time connectivity and enable Volkswagen to trial new smart factory use cases. Dr.-Ing. Klaus-Dieter Tuchs, network planning at Volkswagen, said: “Predictable wireless performance and the real-time capabilities of 5G have great potential for smart factories in the not-so-distant future. With this pilot deployment, we are exploring the possibilities 5G has to offer and are building our expertise in operating and using 5G technology in an industrial context.”

Advisor quote

“We won’t even remember speculating about whether 5G would happen. We’ll be too busy using it to solve networking and IoT installation problems.”

10. Secure remote access of assets is growing in importance

Companies that have enabled remote access to their machines stand to realize several benefits, including better support from equipment suppliers that can remotely troubleshoot and analyze machine data in real-time, as well as access to remote subject matter experts and lower-cost labor (e.g., high-skilled workers from lower-wage countries)

But with increased access comes increased cyber security attack vectors, so companies are subsequently increasing their spending on cybersecurity to address this. Three key use cases for cyber security in 2022 are asset visibility, deep-packet inspection, and zero trust architectures. Asset visibility software provides detailed information about all nodes and users connected to a network, allowing administrators to identify suspicious users or devices quickly. Deep-packet inspection can alert operators of industrial networks when suspicious activity is spotted in the industrial protocols that run these networks. And Zero Trust architectures essentially gives zero trust that networks are secure and (according to NIST) “…moves defenses from static, network-based perimeters to focus on users, assets, and resources.”

Example

The SANS 2021 OT/ICS Cybersecurity report found that remote access services were the dominant threat vector for respondents, with 37% citing remote access as the point of initial access. As a result of the dramatically increased need to mitigate these attacks as the number of remote points increases, IoT security firm Claroty increased its headcount by 75% from pre-pandemic levels through to December 2021.

Advisor quote

“’Remote’ became a household term during the pandemic as millions of people started working from home for the first time, including people managing OT networks and assets, but that very remoteness increased the scale of the threat unsecured remote devices can pose.”

More information and further reading on IoT technology trends

Are you interested in learning more about the topics discussed in this article?

Cloud computing market

Report(s):

- The Cloud Computing Market Report 2021-2026 covers market sizing, competitive landscape, 22 trends and developments, and more.

Industrial AI

Report(s):

- The Industrial AI and AIoT Market Report 2021–2026 includes market sizing, use case analyses, case studies, trends, and more.

- The Industrial AI Software Platform Vendor Landscape Report 2021 showcases 12 detailed analyses of selected industrial AI platforms.

- The Industrial IoT Software Companies Acquisition List 2022 is a list of 260+ upcoming companies operating in the industrial IoT software space (with a focus on AI, industrial machine connectivity or IoT platforms).

Blog post(s):

- The rise of industrial AI and AIoT: 4 trends driving technology adoption

- What are smart factories? 7 misconceptions and a definition

Industrial automation

Report(s):

- The Virtualization in Industrial Automation | Adoption Report 2021 examines the adoption of virtualization in industrial automation.

Blog post(s):

Digital twins and edge computing

Report(s):

- The Digital Twin Insights Report 2020 includes vendor profiles, case studies, trend, challenges and more.

- The Industrial Edge Computing Market Report includes market sizing and forecast, vendor market share analysis, use cases and more.

Blog post(s):

- How the world’s 250 Digital Twins compare? Same, same but different.

- IoT edge computing – what it is and how it is becoming more intelligent

5G

Report(s):

- The 5G Market Report 2019-2025 includes market sizing and forecast, segmentation of the 5G market, vendor profiles, drivers, use cases and more.

Blog post(s):

Predictive maintenance

Report(s):

- The 183-page Predictive Maintenance Market Report 2021-2026 includes details about the market size and outlook, vendor landscape, case studies, trends, challenges and more.

Blog post(s):

Semiconductors

Report(s):

- The IoT Semiconductor Market Report 2020-2025 includes market size and forecast, key segments in the competitive landscape, company profiles, trends and more.

Blog post(s):

- State of IoT 2021: Number of connected IoT devices growing 9% to 12.3 billion globally, cellular IoT now surpassing 2 billion

- 20 million cellular IoT chips missing in 2021 due to global supply shortage as Qualcomm continues to lead the market

Cybersecurity

Report(s):

- The Enterprise Cybersecurity Adoption Report 2021examines 9 common cybersecurity threats, 19 cybersecurity solutions, insights on 99 vendors and more.

Blog post(s):

IoT platforms

Report(s):

- The IoT Platforms Market Report 202-2026 includes market size, shares and outlook, a list of case studies, deep-dives, drivers, trends, challenges and more.

Blog post(s):

Are you interested in continued IoT coverage and updates?

Subscribe to our newsletter and follow us on LinkedIn and Twitter to stay up-to-date on the latest trends shaping the IoT markets. For complete enterprise IoT coverage with access to all of IoT Analytics’ paid content & reports including dedicated analyst time check out Enterprise subscription.